Tea Time

Created on 27 Nov 2015

Are you tired of ordering milk tea all the time to only find it to be too sweet or lack tea flavor?

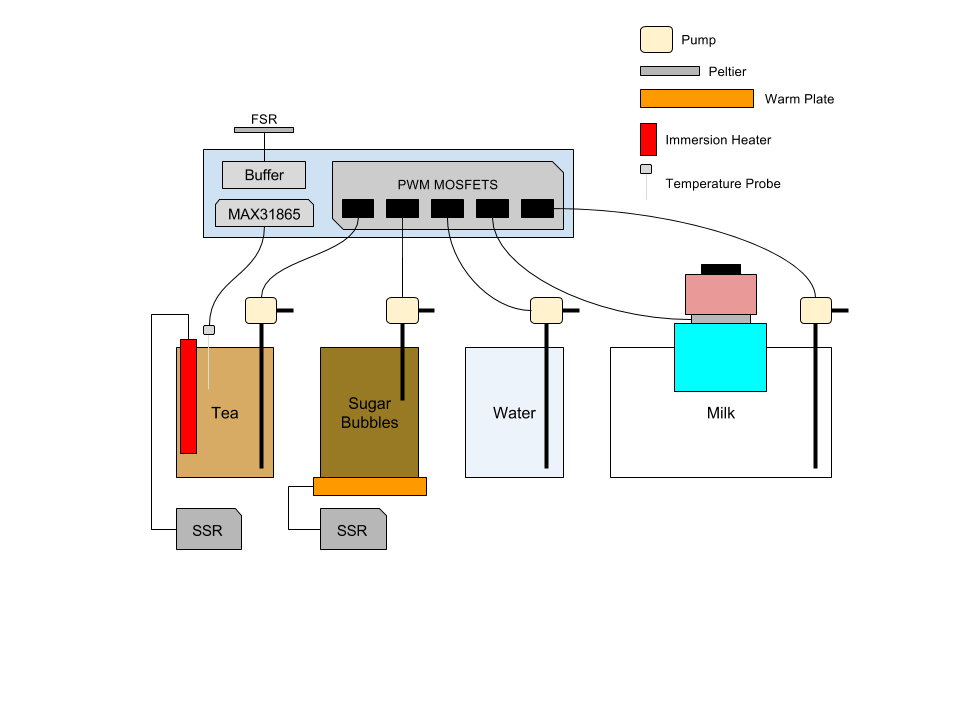

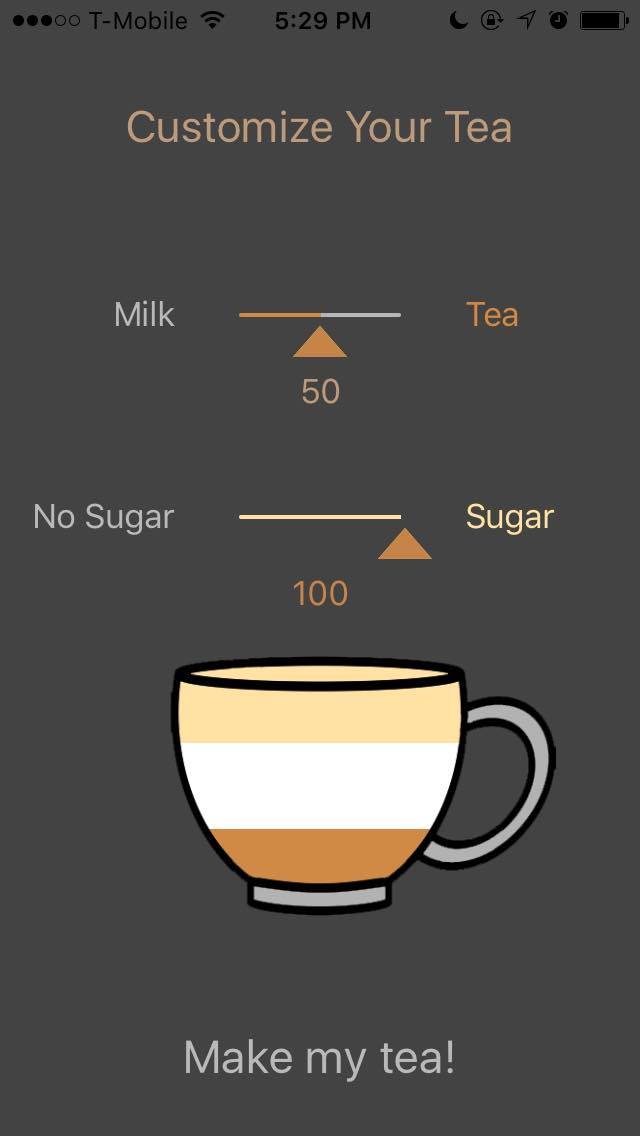

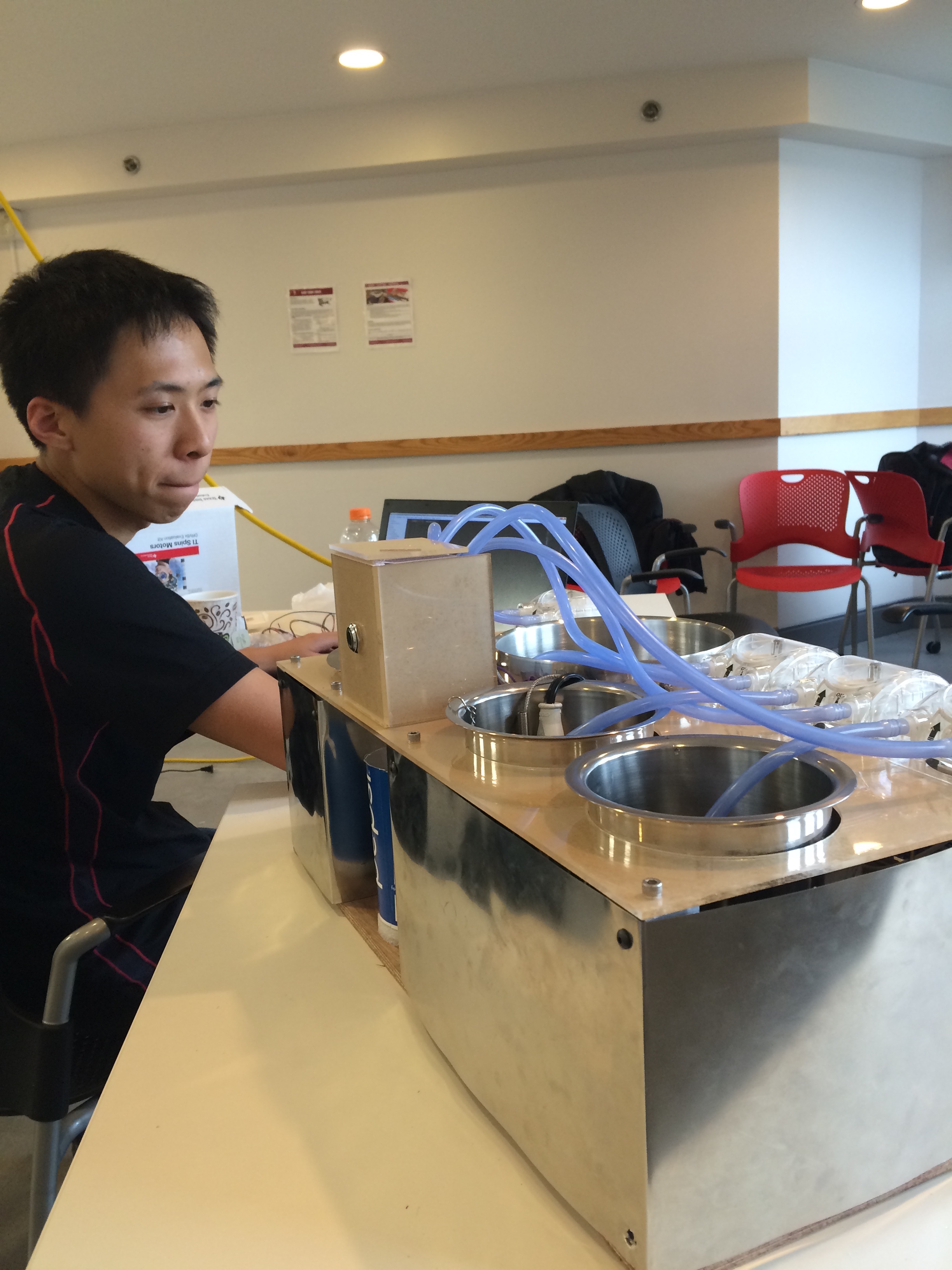

An automated milk tea machine which dispenses your custom ratio of tea, fresh milk, and sugar, with a companion iPhone app to customize your tea wirelessly. The only way to get good milk tea in Pittsburgh is to make it yourself.

Check out our code at:

https://github.com/starsword829/MTM

Edwin Cho

28 Nov 2015, 6:50 p.m. EST

Draft Block diagram created

Edwin Cho

28 Nov 2015, 6:50 p.m. EST

Draft Parts List Created

Edwin Cho

05 Dec 2015, 10:58 p.m. EST

Added Power Supply

Edwin Cho

14 Jan 2016, 2:30 a.m. EST

1/11: Meet with group to plan roles and check for missing components.

Tiffany Chiang

15 Jan 2016, 12:16 a.m. EST

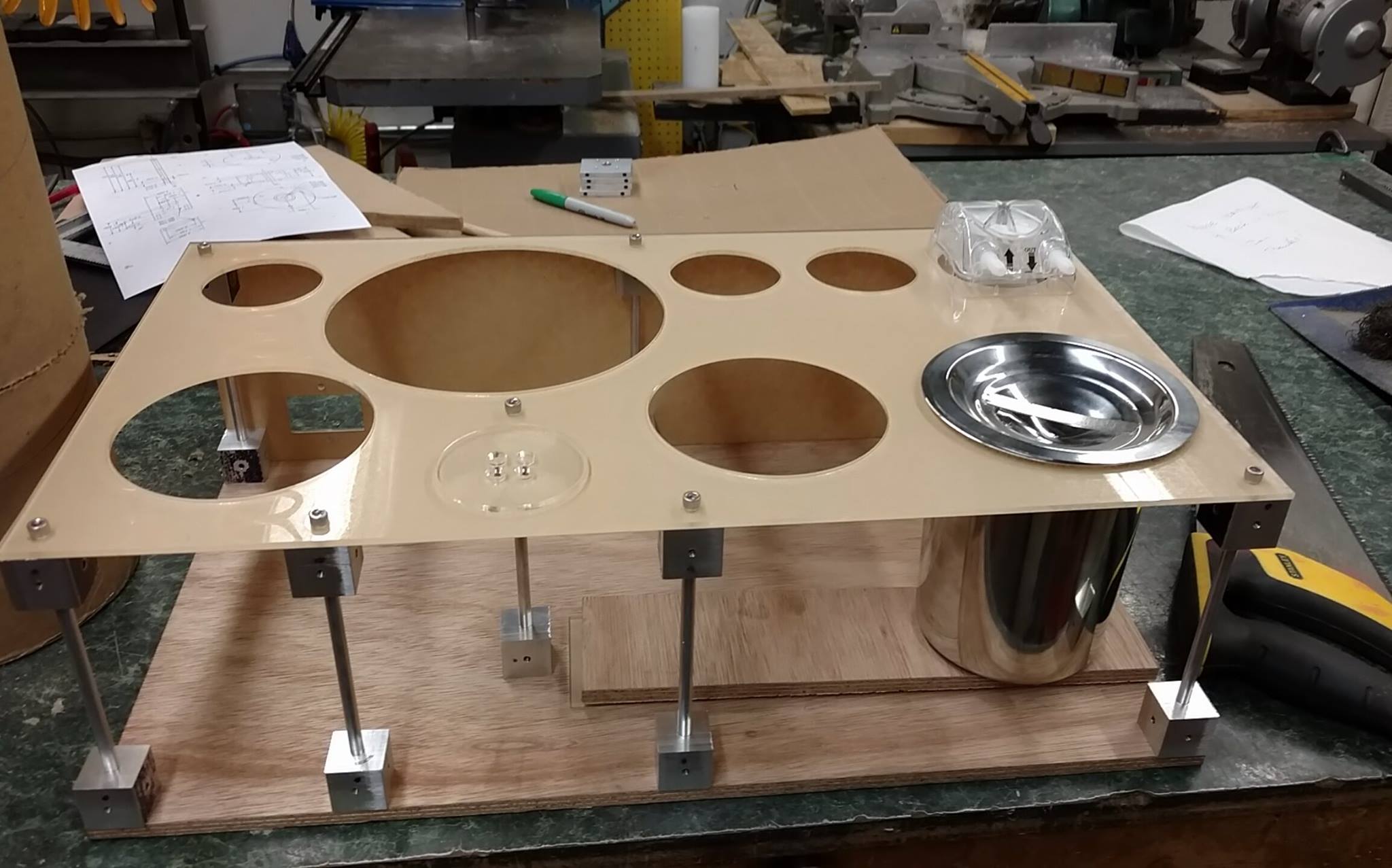

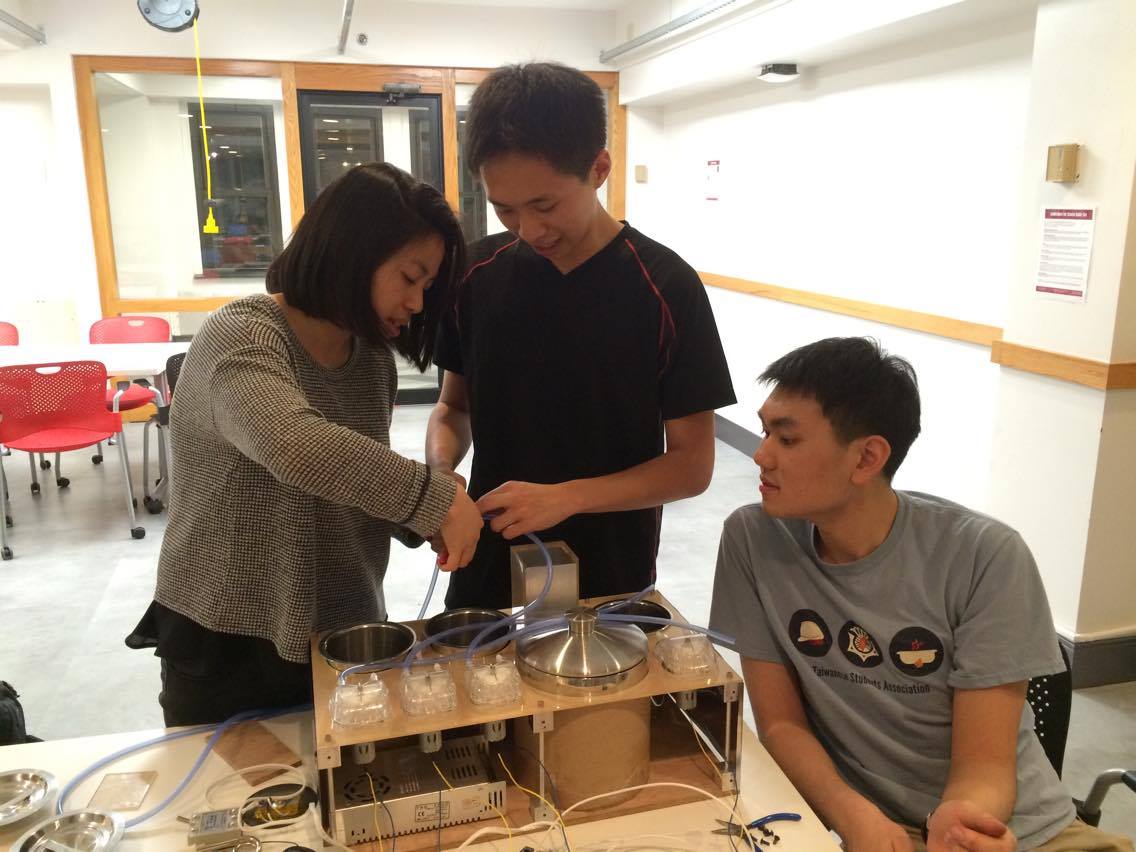

1/14: Tea enclosure complete, final assembly underway.

Edwin Cho

14 Jan 2016, 2:29 a.m. EST

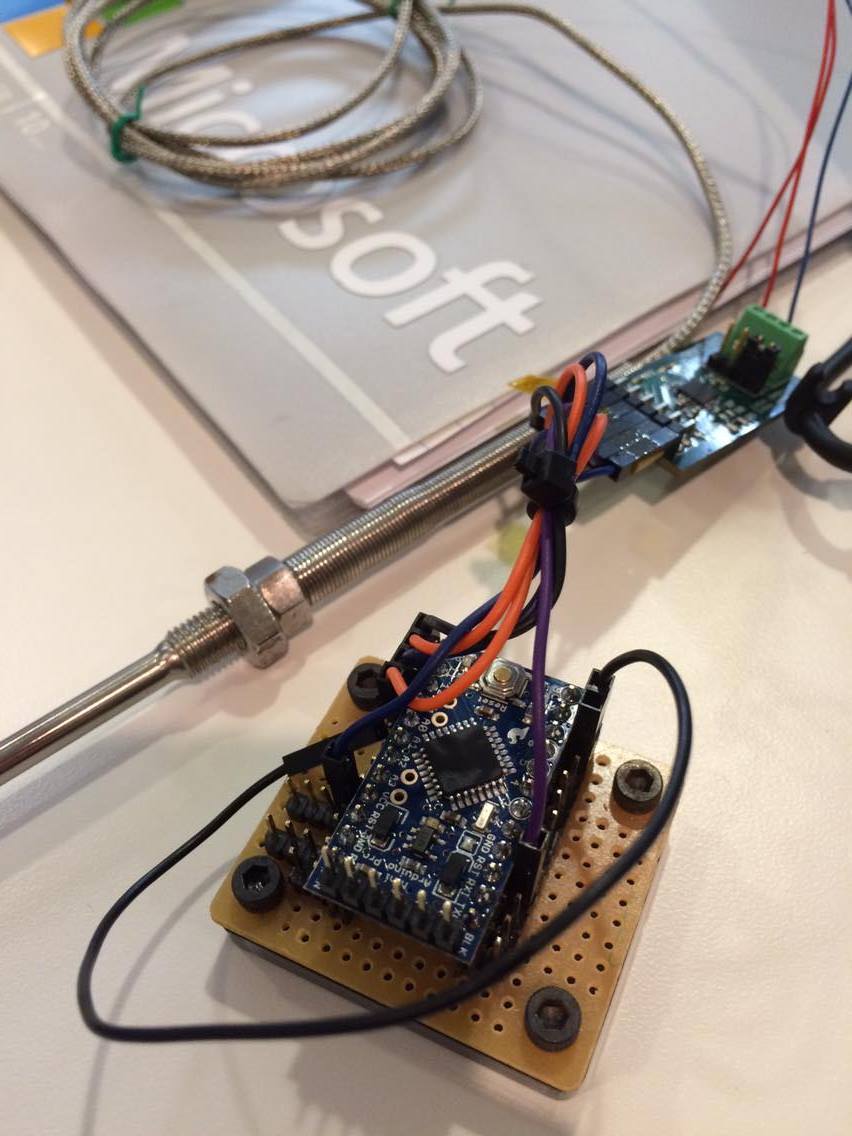

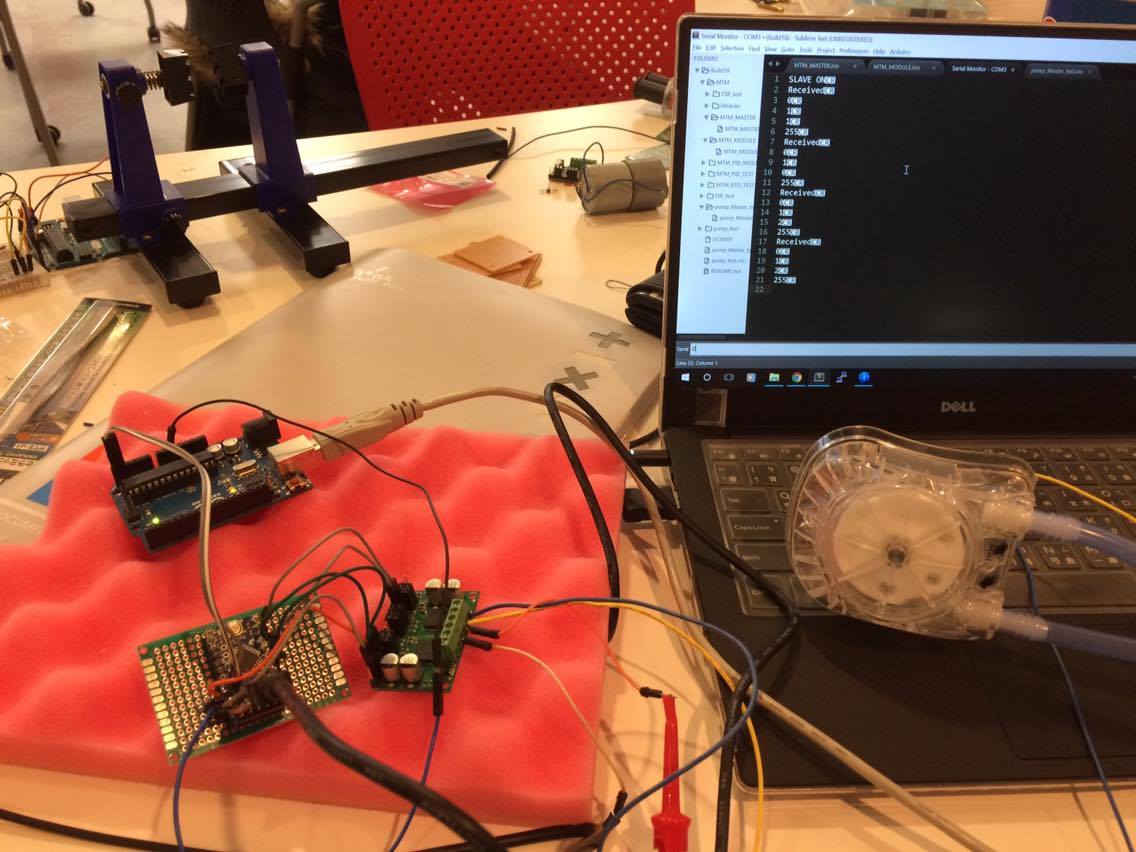

1/12: All components tested: FSR tuned and working, pumps tested with motor driver, RTD fixed and now working, and finalized architecture and protocol.

Tiffany Chiang

15 Jan 2016, 12:17 a.m. EST

1/15: Tea enclosure complete, final assembly underway.

Tiffany Chiang

15 Jan 2016, 12:37 a.m. EST

1/15: hello

Edwin Cho

14 Jan 2016, 2:21 a.m. EST

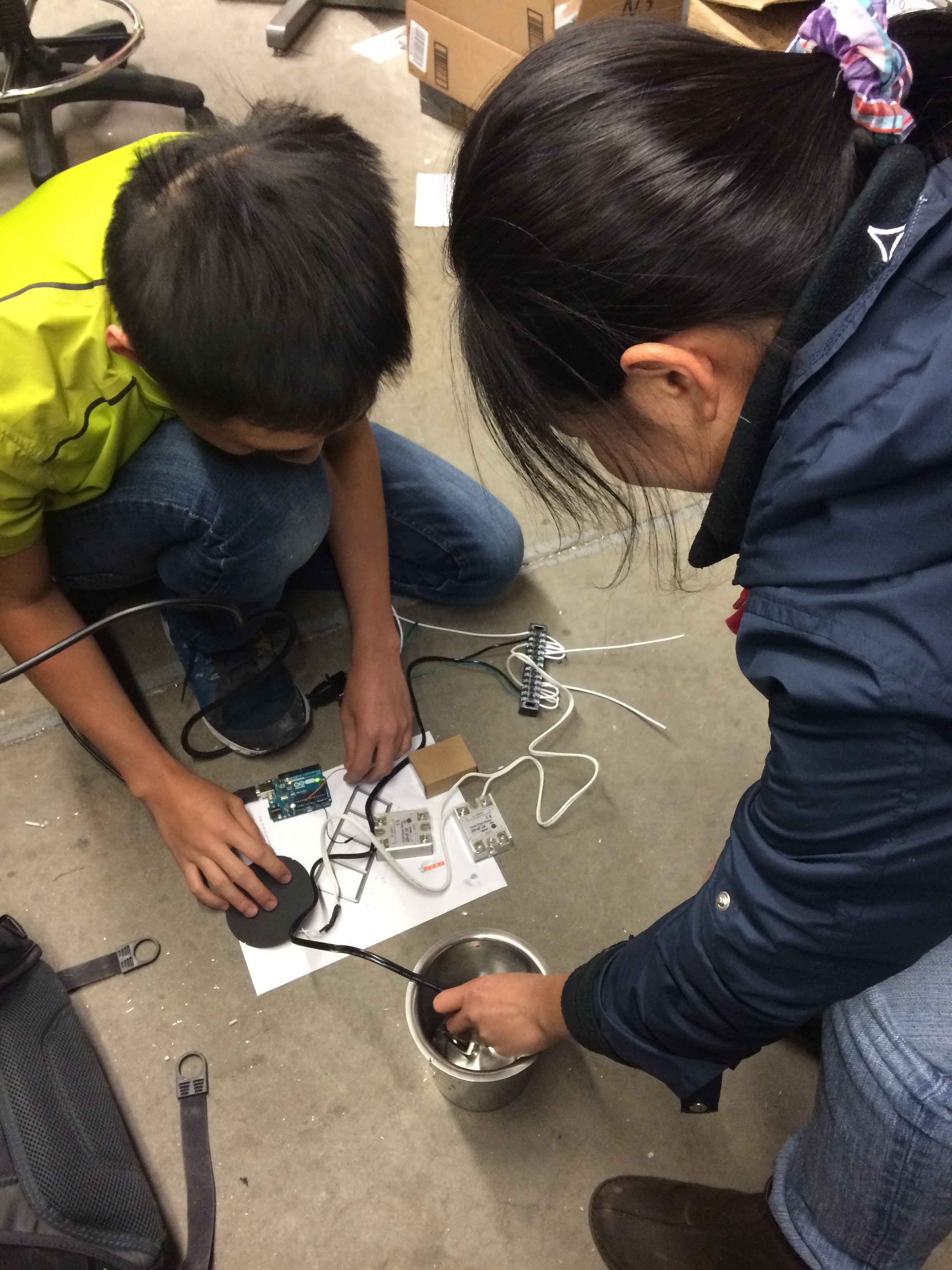

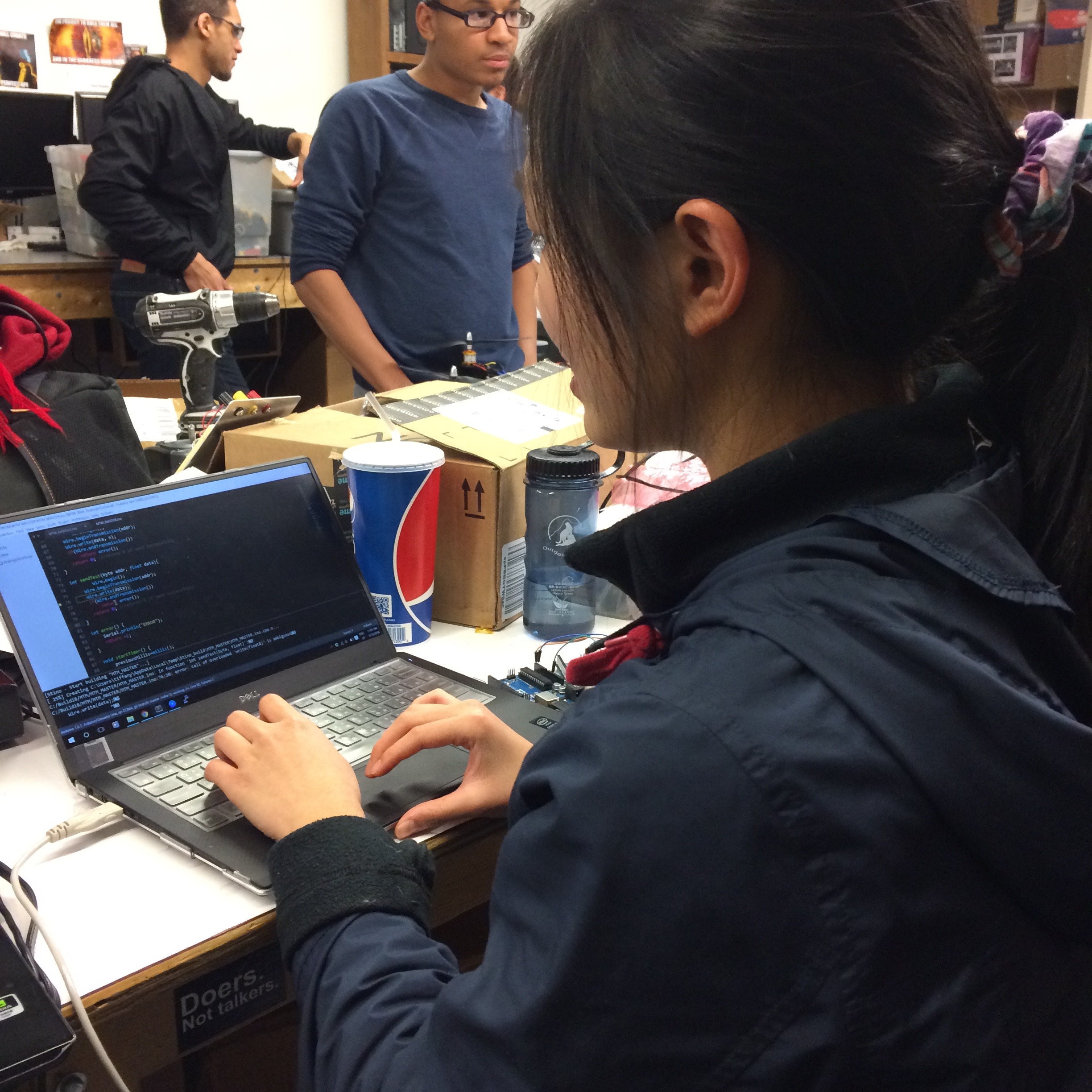

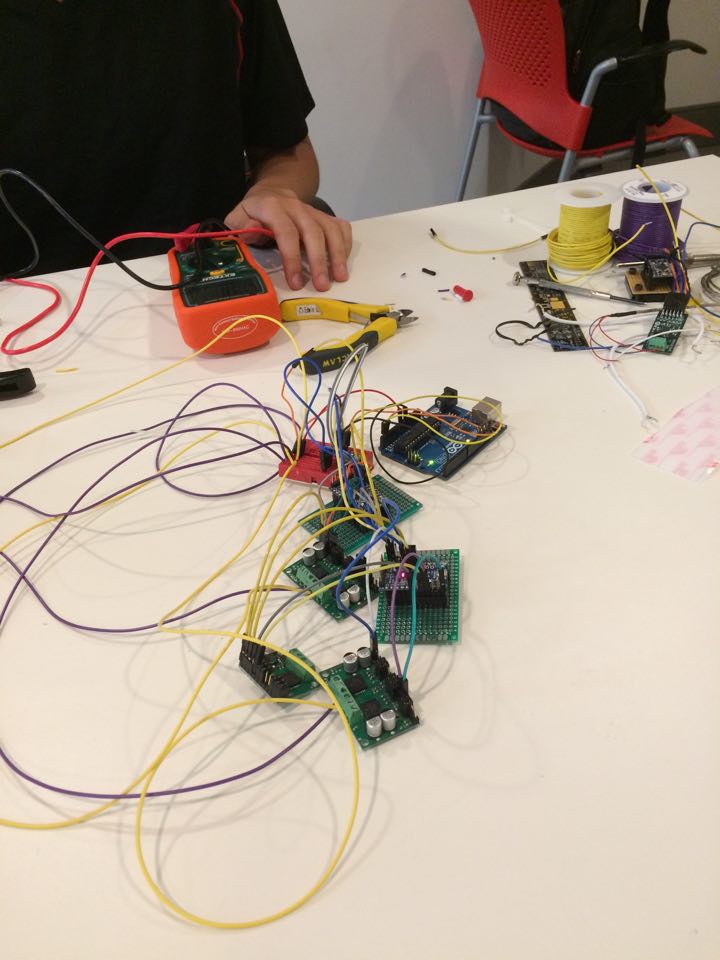

1/13: Master and module code written and tested with partial hardware. AC wiring completed, and began soldering onto perfboards. Begin working on PID tuning of water heater.

Edwin Cho

14 Jan 2016, 2:27 a.m. EST

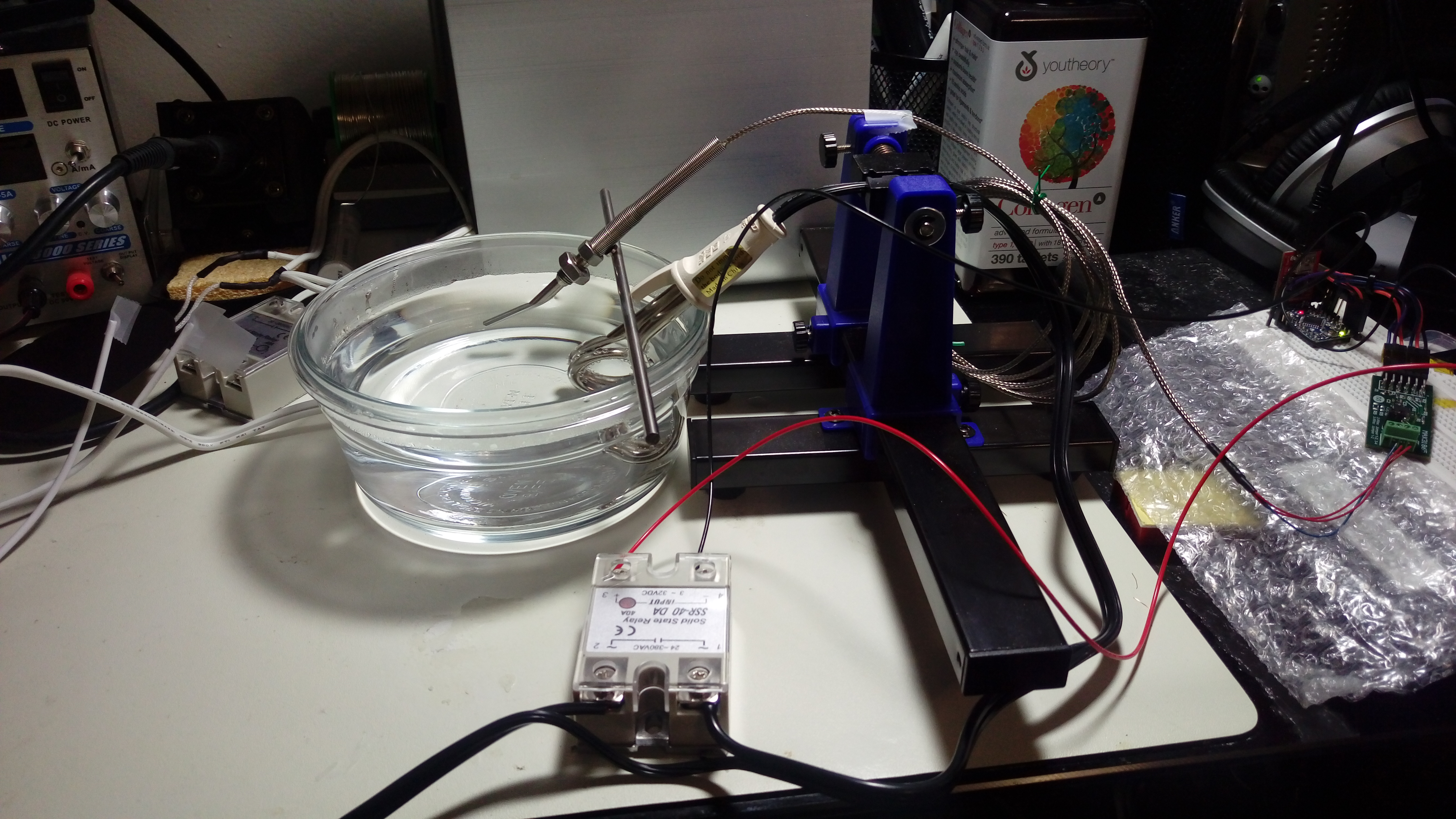

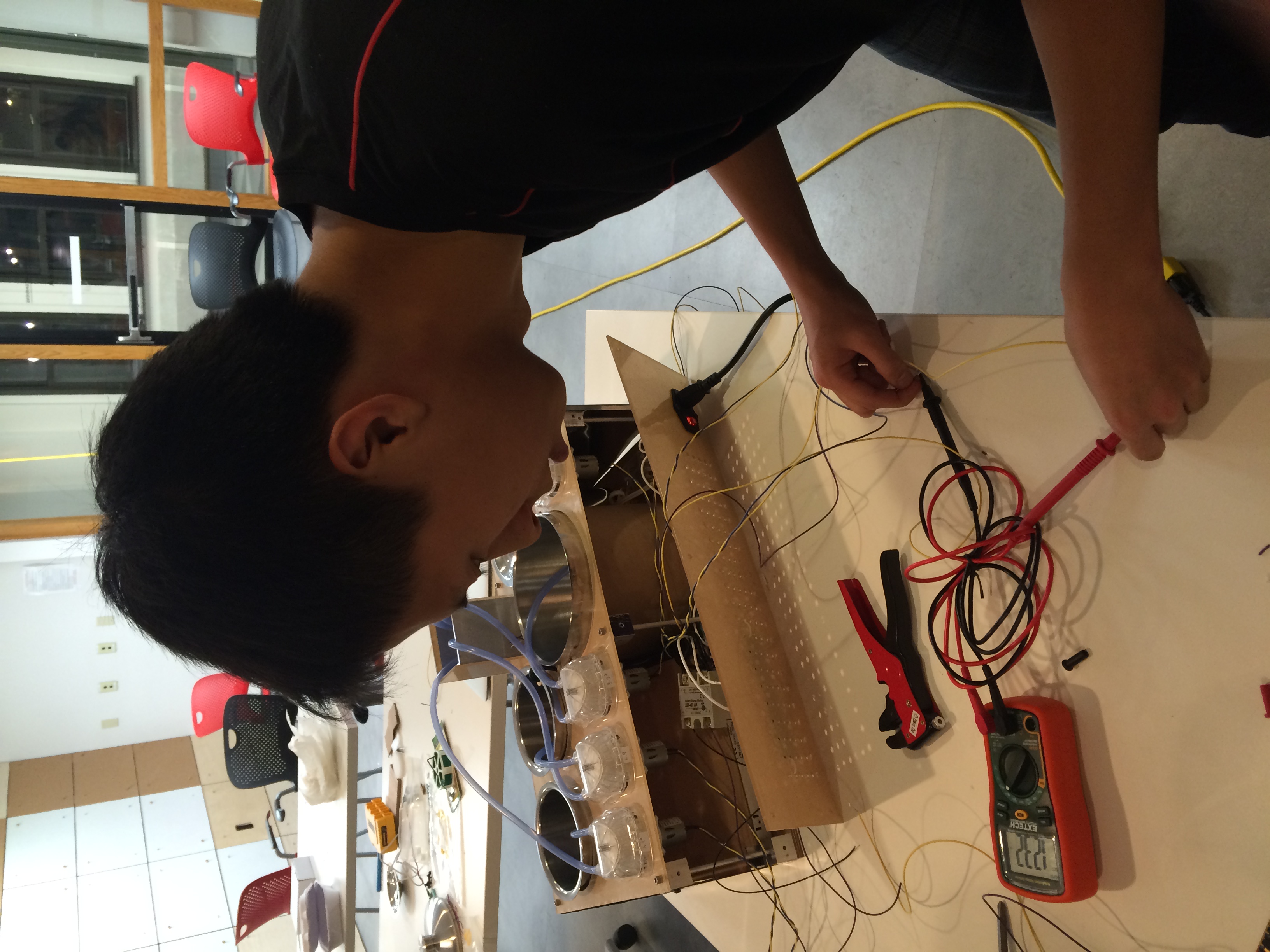

1/14: Tuning PID

Edwin Cho

14 Jan 2016, 2:49 a.m. EST

1/14: SSR for water heating slightly warm will require basic heatsink

Edwin Cho

14 Jan 2016, 3:39 a.m. EST

1/14: Kp 15.94, Ki 0.08, Kd 0.00 works but might need more gain

Jaime Chu

15 Jan 2016, 1:06 a.m. EST

Beginning assembly

Edwin Cho

14 Jan 2016, 6:03 a.m. EST

1/14: Wrote PID module, and system seems robust enough. Still need to improve settle time. Max temperature is around 97C. Still need to see if the controller can handle PID control with pump control concurrently.

Jaime Chu

14 Jan 2016, 4:13 p.m. EST

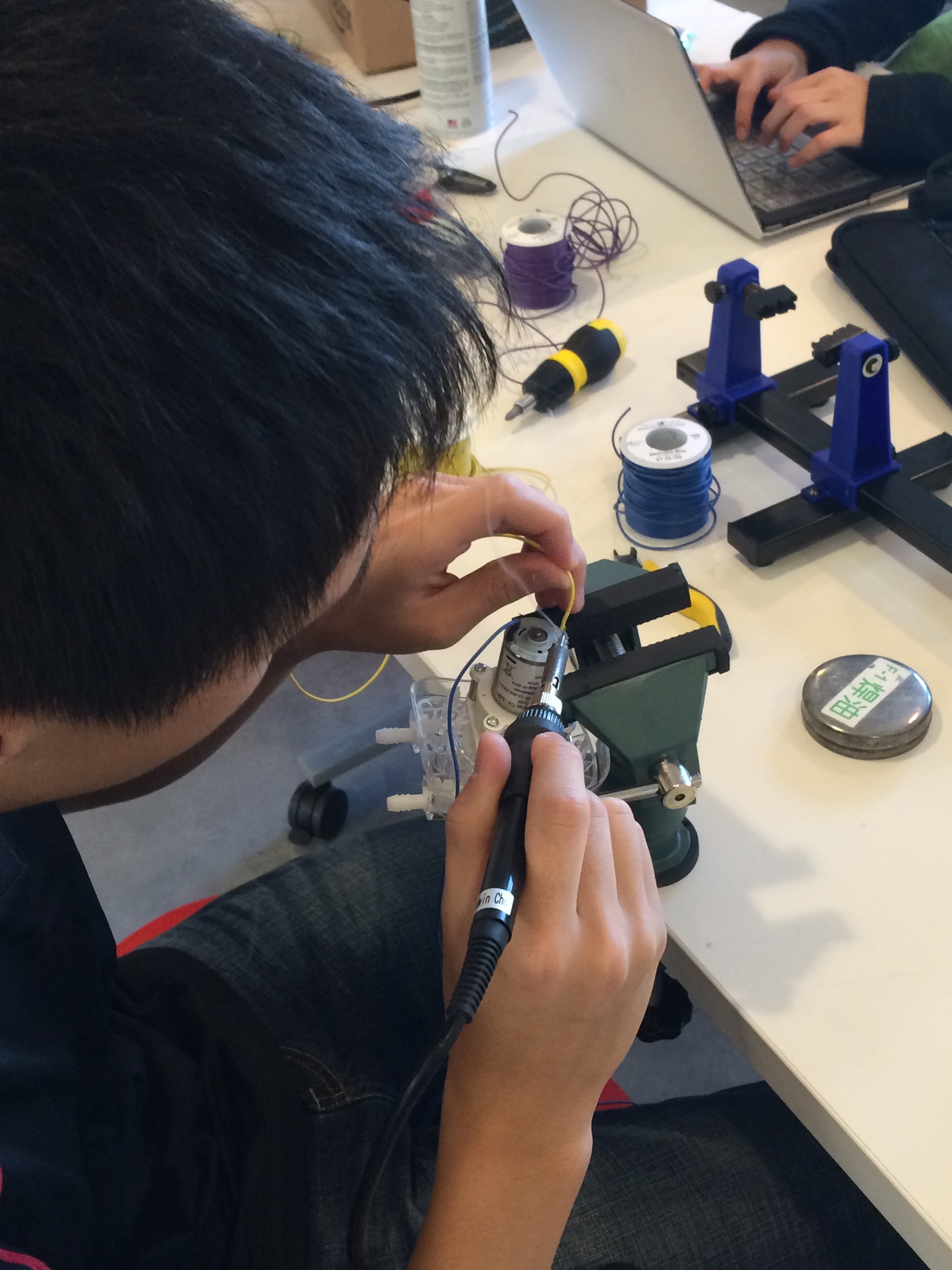

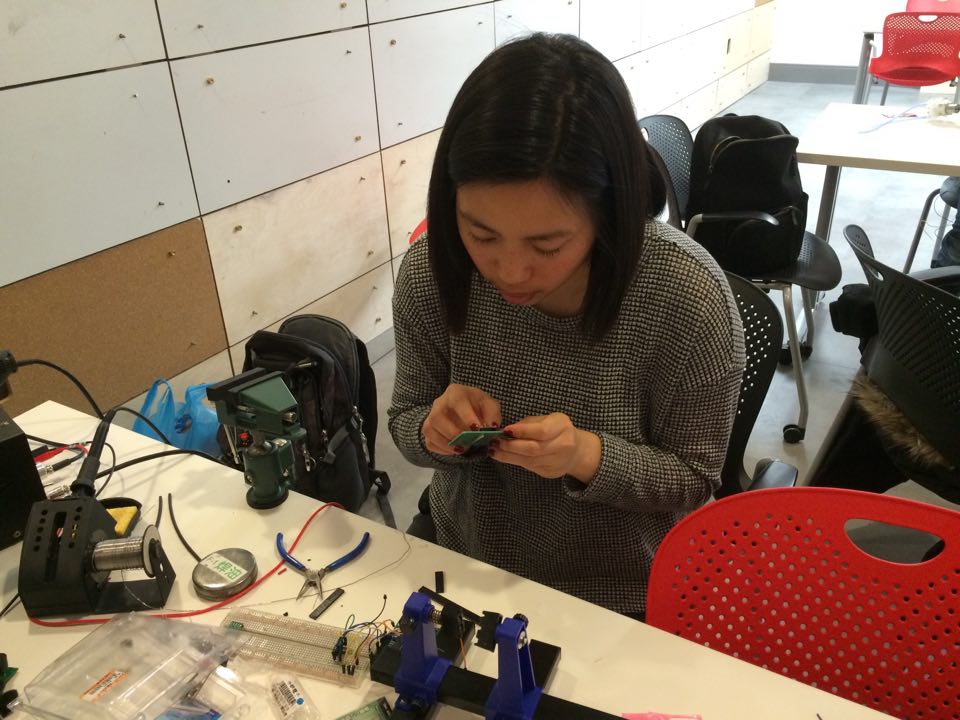

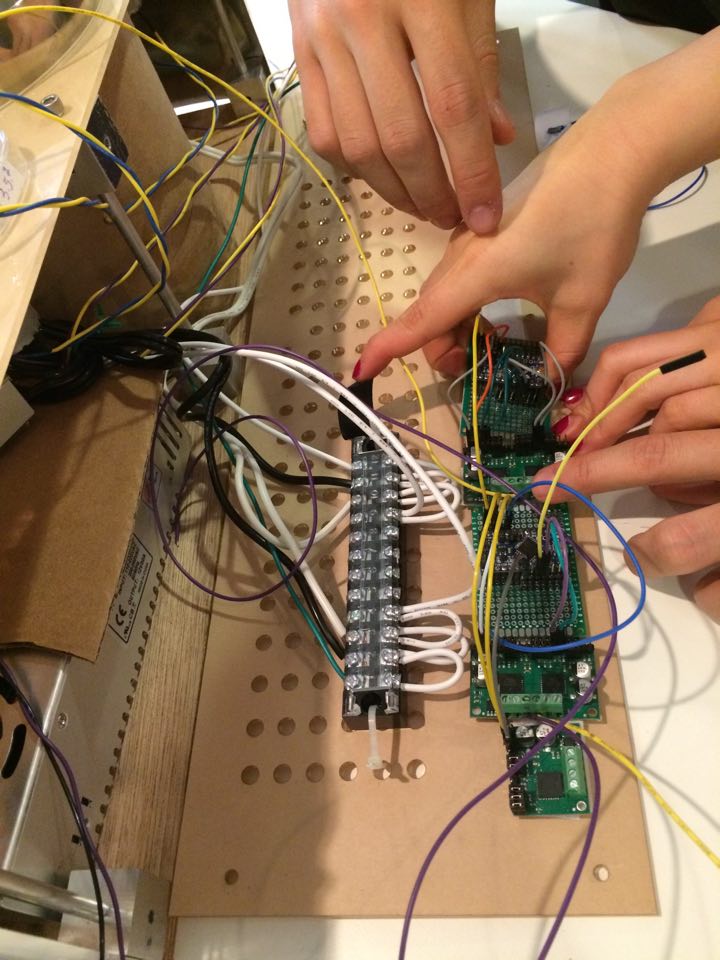

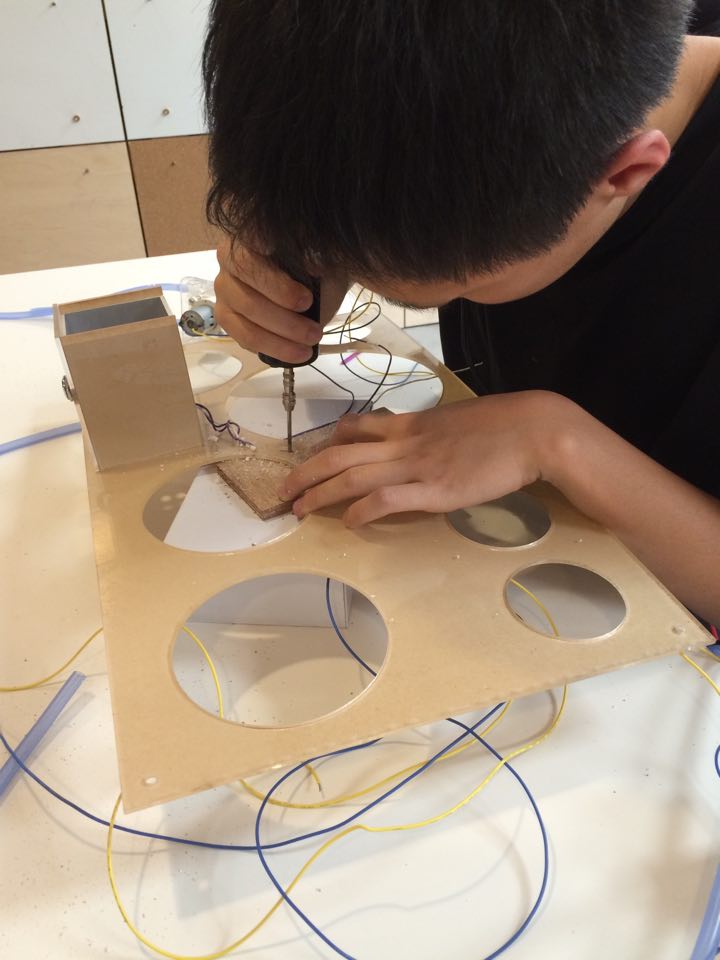

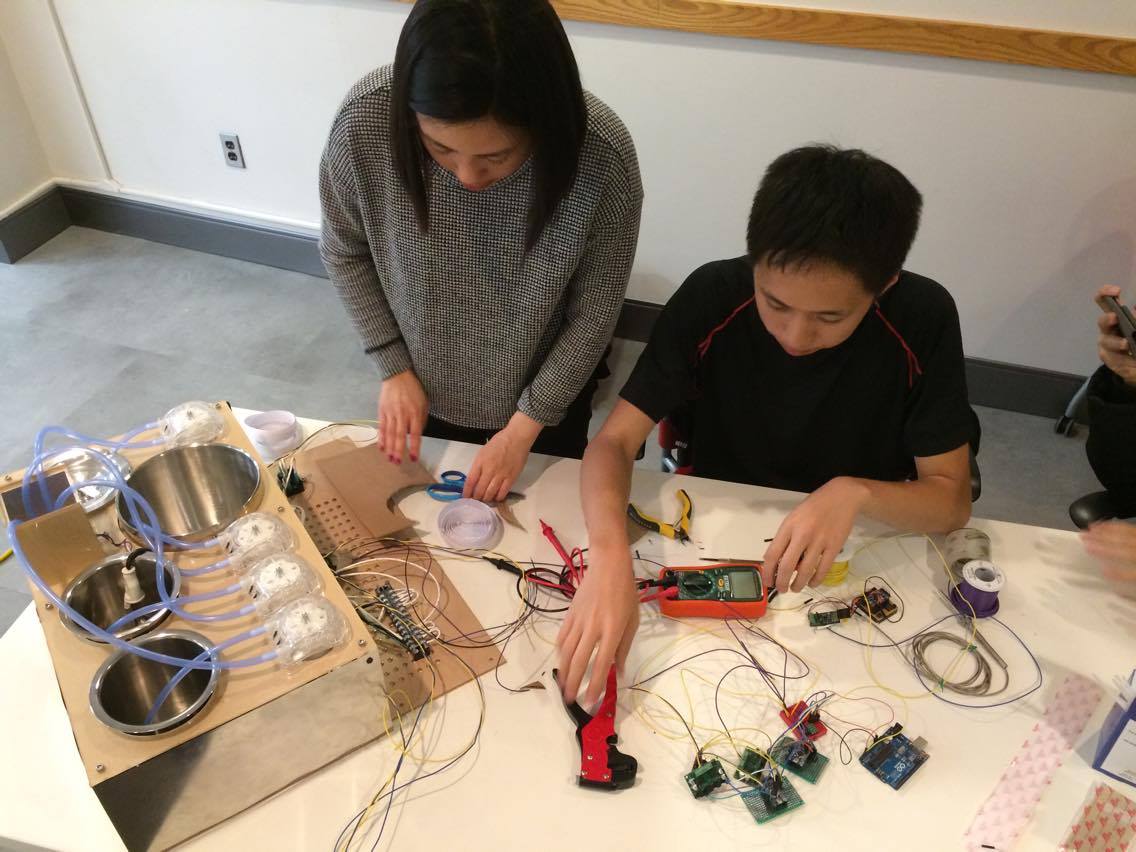

1/14: Beginning to solder FSR (Force Sensitive Resistor), RTD (Resistive Thermometer Device) onto perfboards and will mainly do testing and integration of the final boards. Finishing up the mechanics (including tapping blocks to connect each structural piece for the final demo).

Jaime Chu

15 Jan 2016, 1:07 a.m. EST

1/15: Beginning assembly !

Jaime Chu

14 Jan 2016, 7:58 p.m. EST

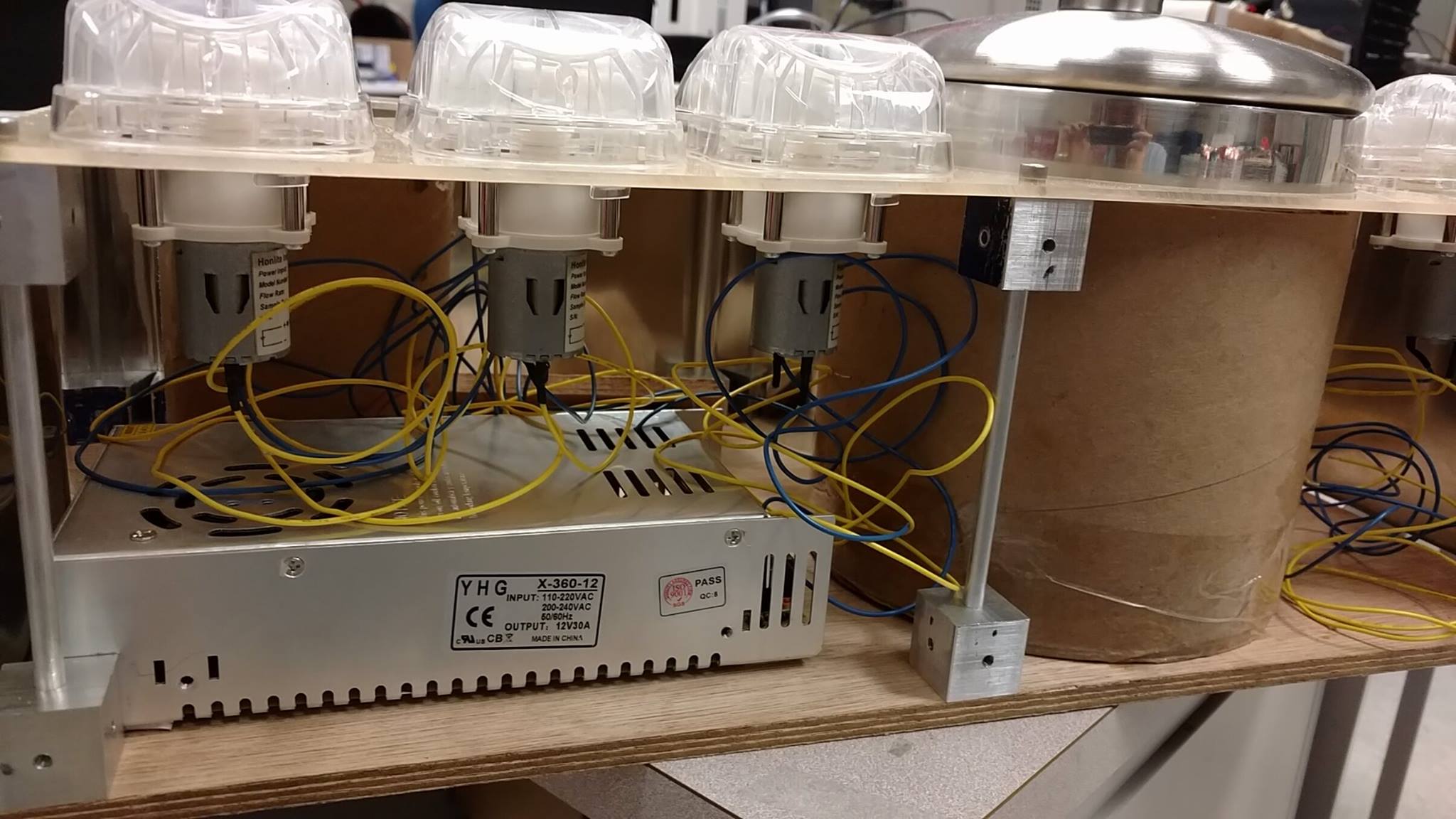

1/14: Mechanics are looking good. The structure is forming, and things are beginning to be put together. (See image)

Tiffany Chiang

14 Jan 2016, 9:36 p.m. EST

1/14: Successfully sent FSR data from master to slave.

Tiffany Chiang

14 Jan 2016, 11:14 p.m. EST

1/14: Soldered RTD and FSR to perf boards. Sub-system testing.

Jaime Chu

14 Jan 2016, 11:38 p.m. EST

1/14: Successfully communicated iOS app to Photon microcontroller.

Jaime Chu

15 Jan 2016, 5:32 a.m. EST

1/15: 5:30AM We're all energized after plugging things into the outlet. AC/DC converter did not blow up after wiring and outputs correct voltage.

Tiffany Chiang

15 Jan 2016, 6 a.m. EST

1/15 5:57 Connected and tested all hardware (except RTD), velcro-ed all units into tea enclosure. Testing pumps with water soon!

Tiffany Chiang

15 Jan 2016, 12:15 a.m. EST

1/14: Tea enclosure complete, final assembly underway.

Tiffany Chiang

15 Jan 2016, 12:13 a.m. EST

1/14: Tea enclosure complete, final assembly underway.

Tiffany Chiang

15 Jan 2016, 4:29 a.m. EST

1/15 4:27AM All motors wired and running with test master/slave program

Edwin Cho

15 Jan 2016, 5:14 a.m. EST

1/15: 5:12AM Broken motor controller from the past causing problems. Solution found and applying. The morning is slightly getting louder. Hope is fading and time is running out. Heads are dropping one by one. A trip to roboclub from the makerspace has revitalized one. Maybe we should go run in circles. 2PM!

Tiffany Chiang

15 Jan 2016, 6:38 a.m. EST

1/15 6:33AM Final touches to the UI. Currently rewiring all modules to centralized power distribution and I2C. Edwin and Jaime are hungry and tired. Justin and Tiffany are just tired.

Edit: Edwin is not tired.

Jaime Chu

15 Jan 2016, 7:25 a.m. EST

1/15: T -6 hours until demo. One comrade has fallen. Morning alarms have gone off. Still working on assembly of circuits into the main housing.

Edwin Cho

15 Jan 2016, 9:31 a.m. EST

1/15: 9:30AM Blood has been spilled. Found a problem where a pin wasn't soldered. All pumps are running. Our fuel is low and we have to wire stuff outside.

Jaime Chu

15 Jan 2016, 10:46 a.m. EST

1/15: Minor setback - forgot to solder a pin, all motor controllers work. Peristaltic pumps are now pumping water into cups!

Jaime Chu

15 Jan 2016, 5:39 p.m. EST

1/15: Successful demo, now waiting for banquet to start!