One Wheel From Two

Created on 19 Oct 2021

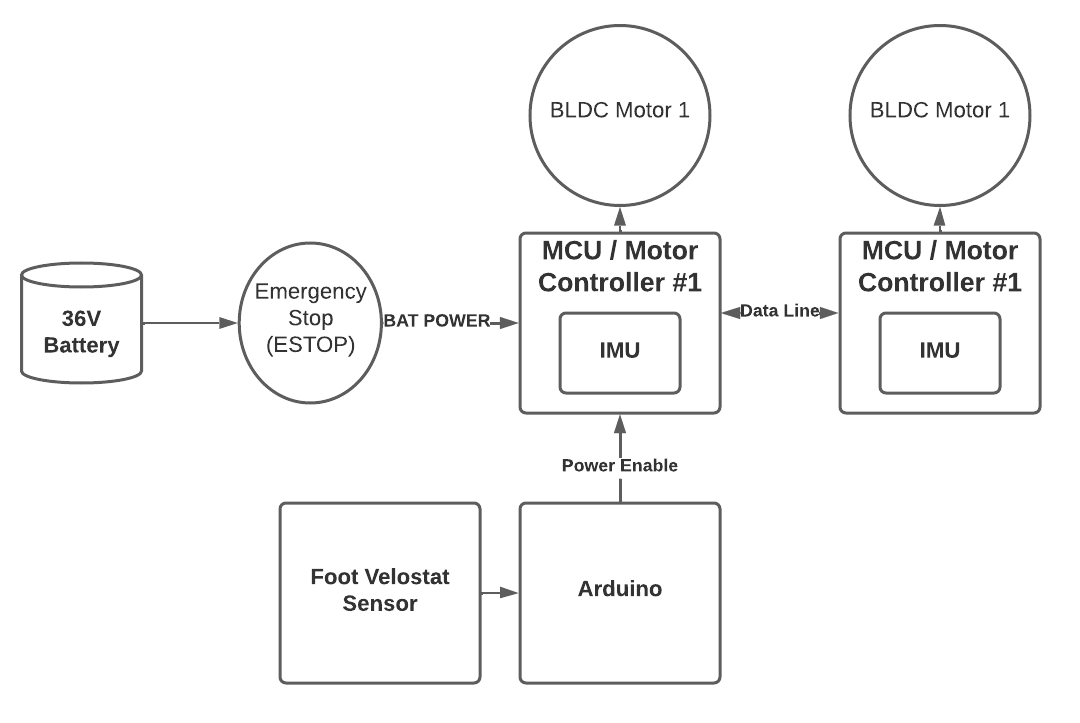

If you can't afford a One Wheel like those grad students outside CIC who let you ride it, just convert a hoverboard!

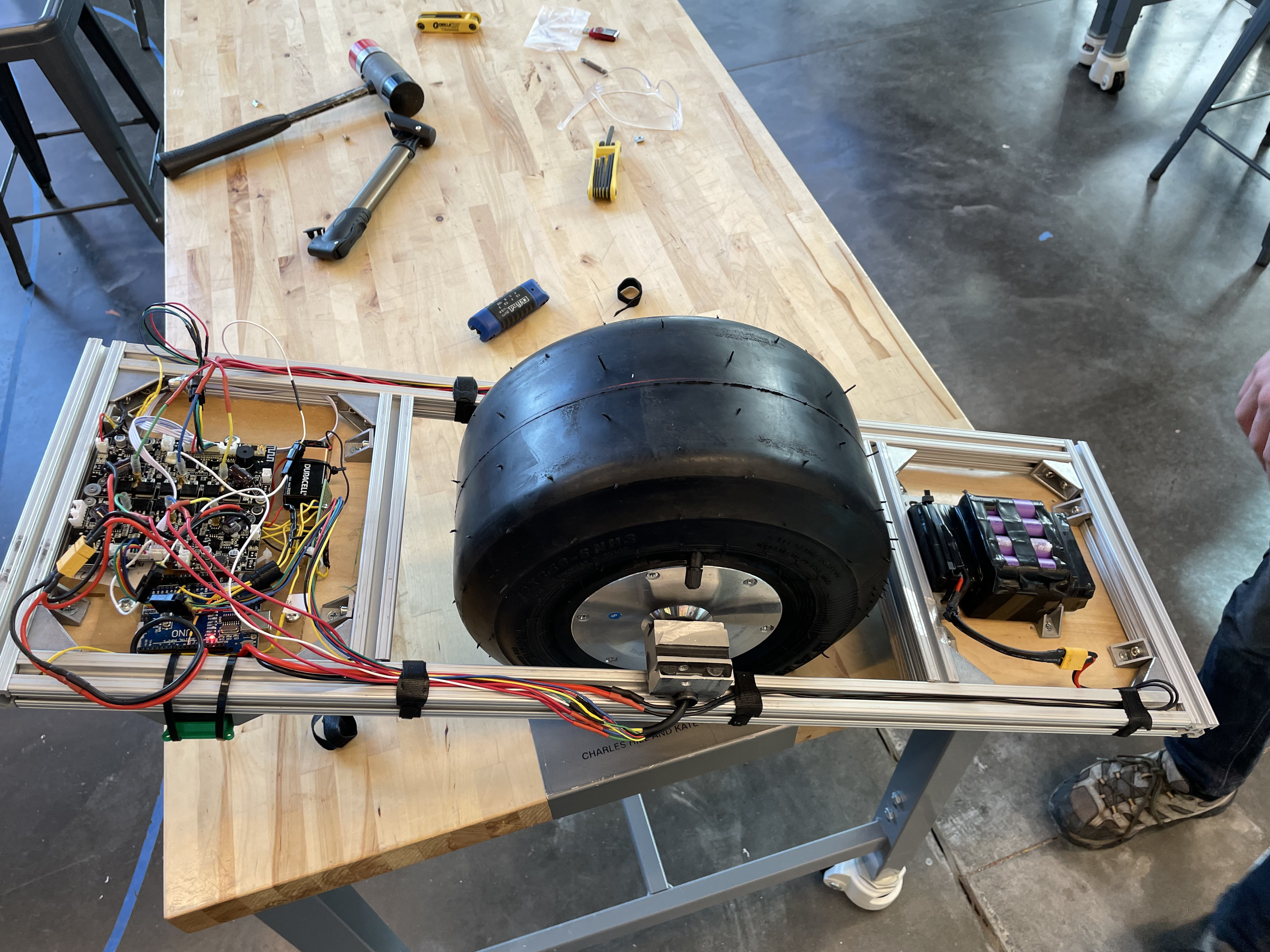

Turned a cheap hoverboard into a One Wheel by reconfiguring parts and machining new ones. Its so slow you can't possibly get hurt! Will include some speed and range mods for those with a bigger budget hehe ;)

| Part | Cost | Quantity | Total |

| The Frame | $28.03 | 1 | $28.03 |

| 5 feet of 1"x2" OD 6061 Aluminum U-channel | |||

| The Tire | $29.15 | 1 | $29.15 |

| 13x6.5-6 Tire for drag-racing lawnmowers | |||

| The Tube | $11.99 | 1 | $11.99 |

| Inner tube for the tire to ensure a smooth ride | |||

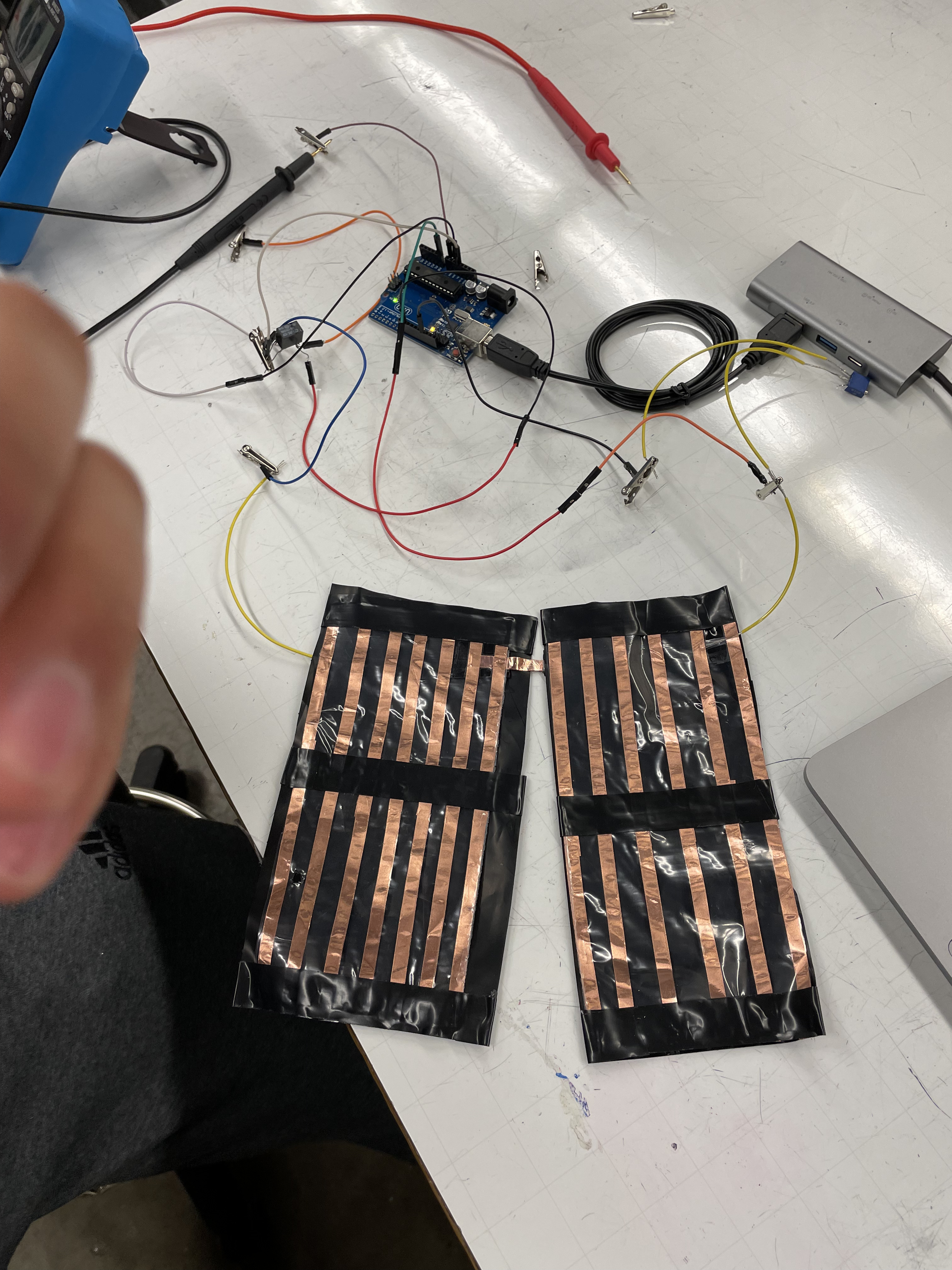

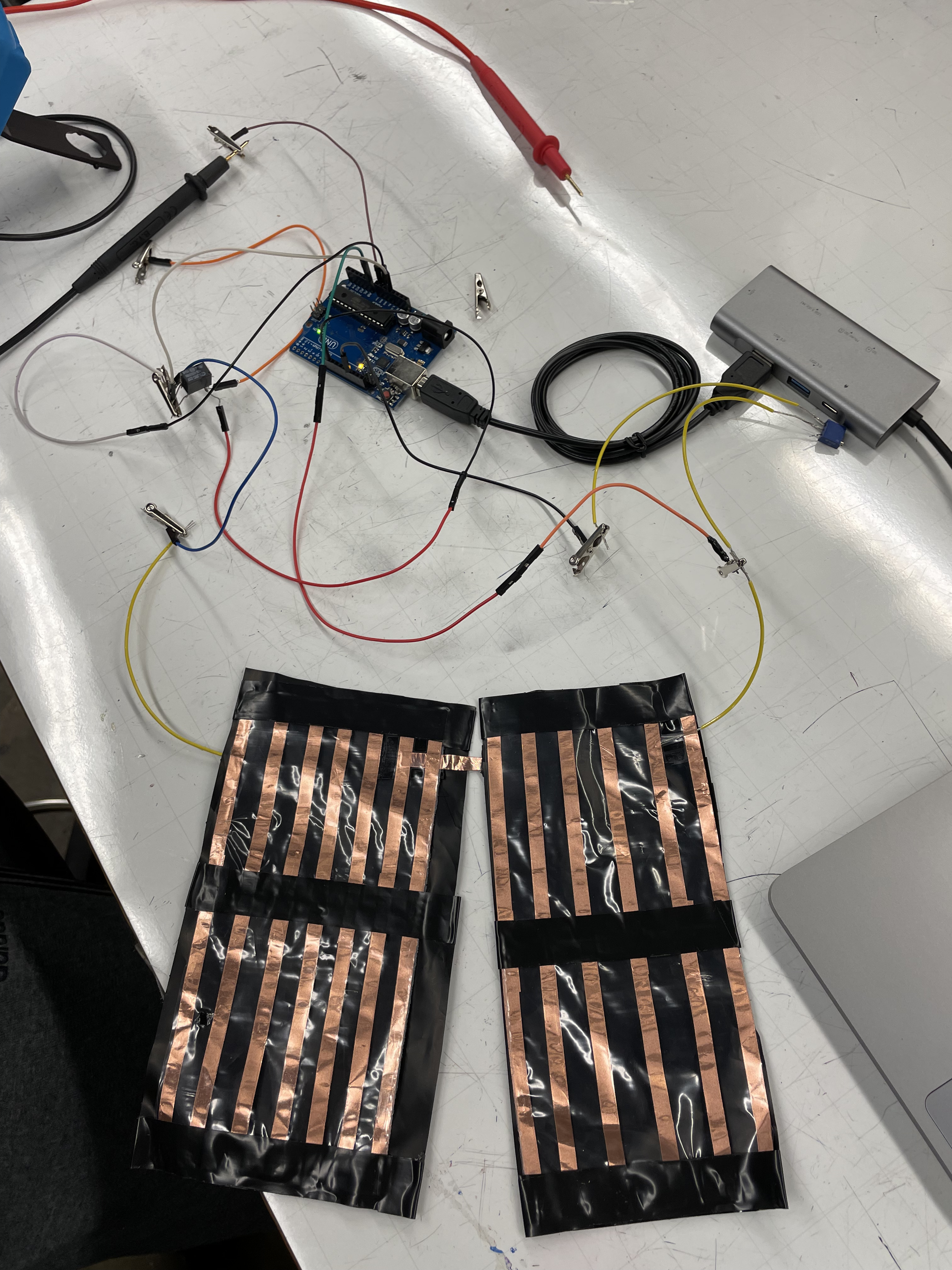

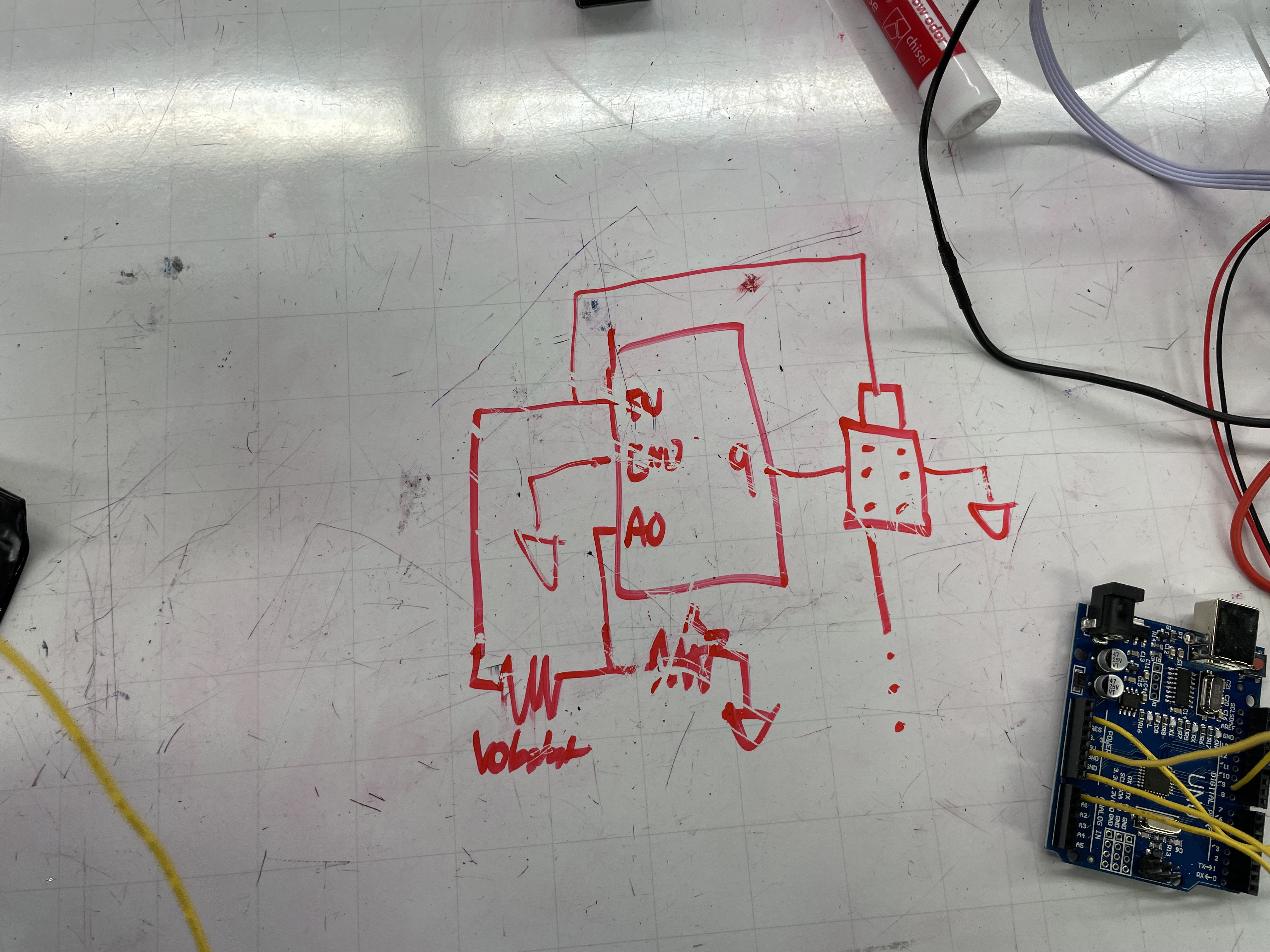

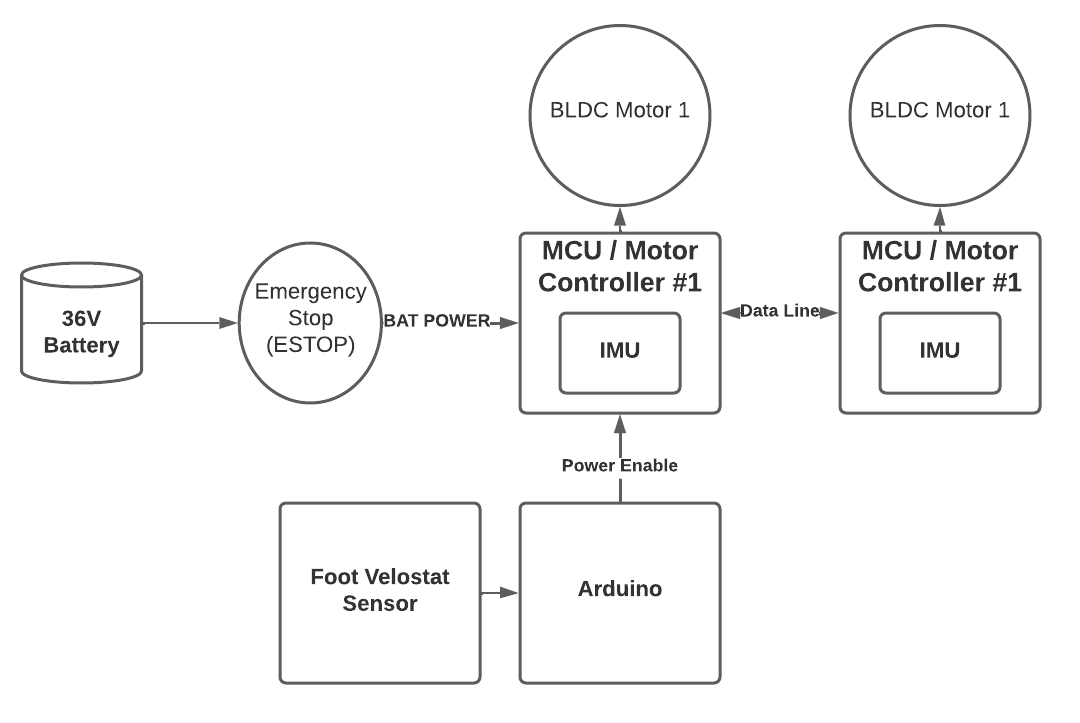

| The Foot Sensor | $4.95 | 1 | $4.95 |

| Flexible resistive velostat sensor for foot control | |||

| The Backup Wheels | $3.60 | 2 | $7.20 |

| Casters for the front to mitigate nose-dive accidents (which will never happen of course) | |||

| The hoverboard | $155.00 | 1 | $155.00 |

| 700W Hoverboard with 8.5 in wheels to be converted into a one wheel (from Alibaba = forsure legit!) | |||

| The power | $4.95 | 1 | $4.95 |

| 30V/10A Digital voltmeter/ampmeter to display battery pack voltage and current draw | |||

| The Grip | $8.99 | 1 | $8.99 |

| Grip Tape for traction | |||

| Project Totals: | 9 | $250.26 | |

| Track 1 Base Budget: | $250.00 | ||

| Preferred Vendor Budget Bonus: | $0.00 | ||

| Remaining Budget: | $-0.26 | ||

Alby Penney

13 Feb 2022, 2:06 p.m. EST

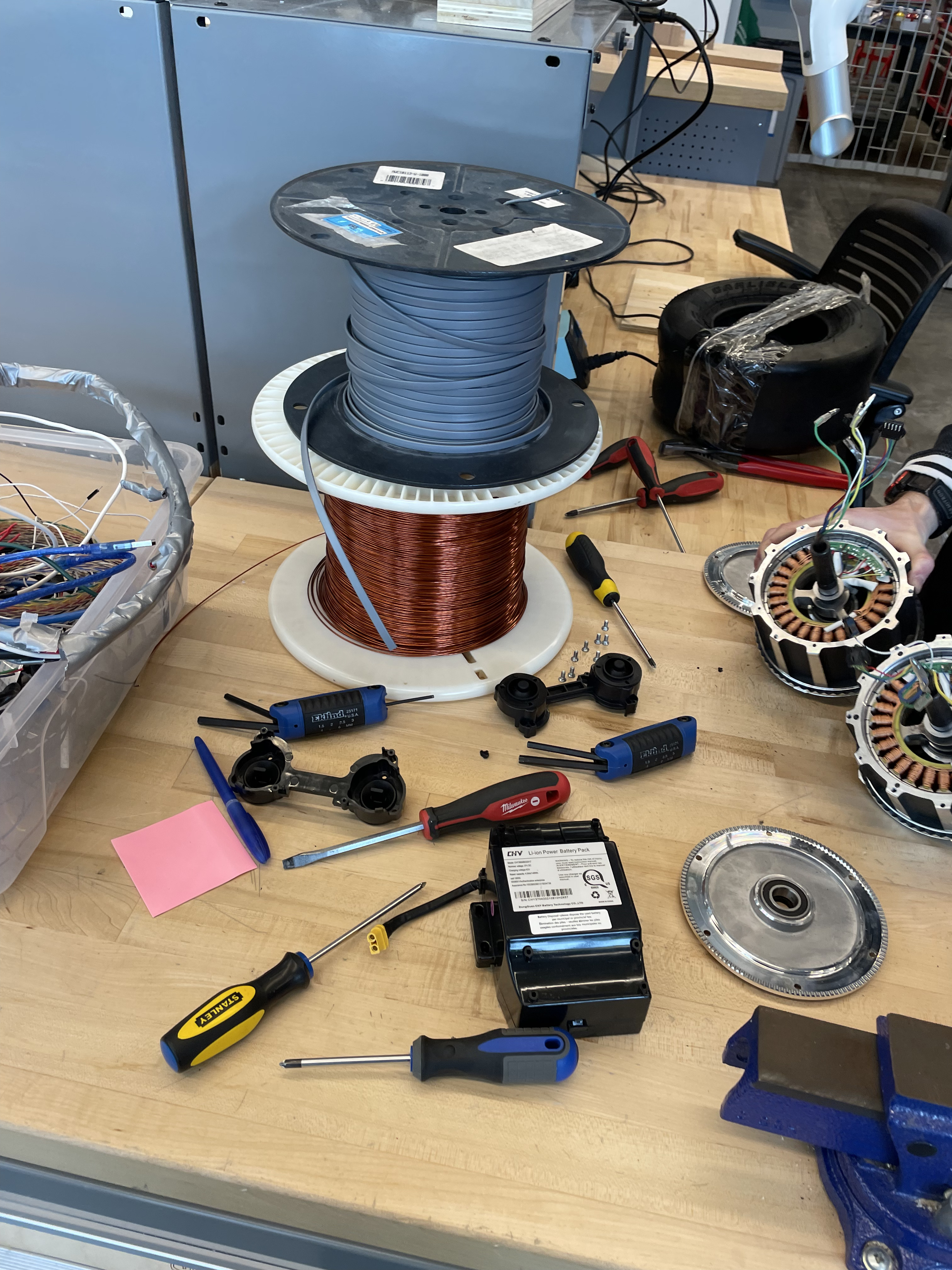

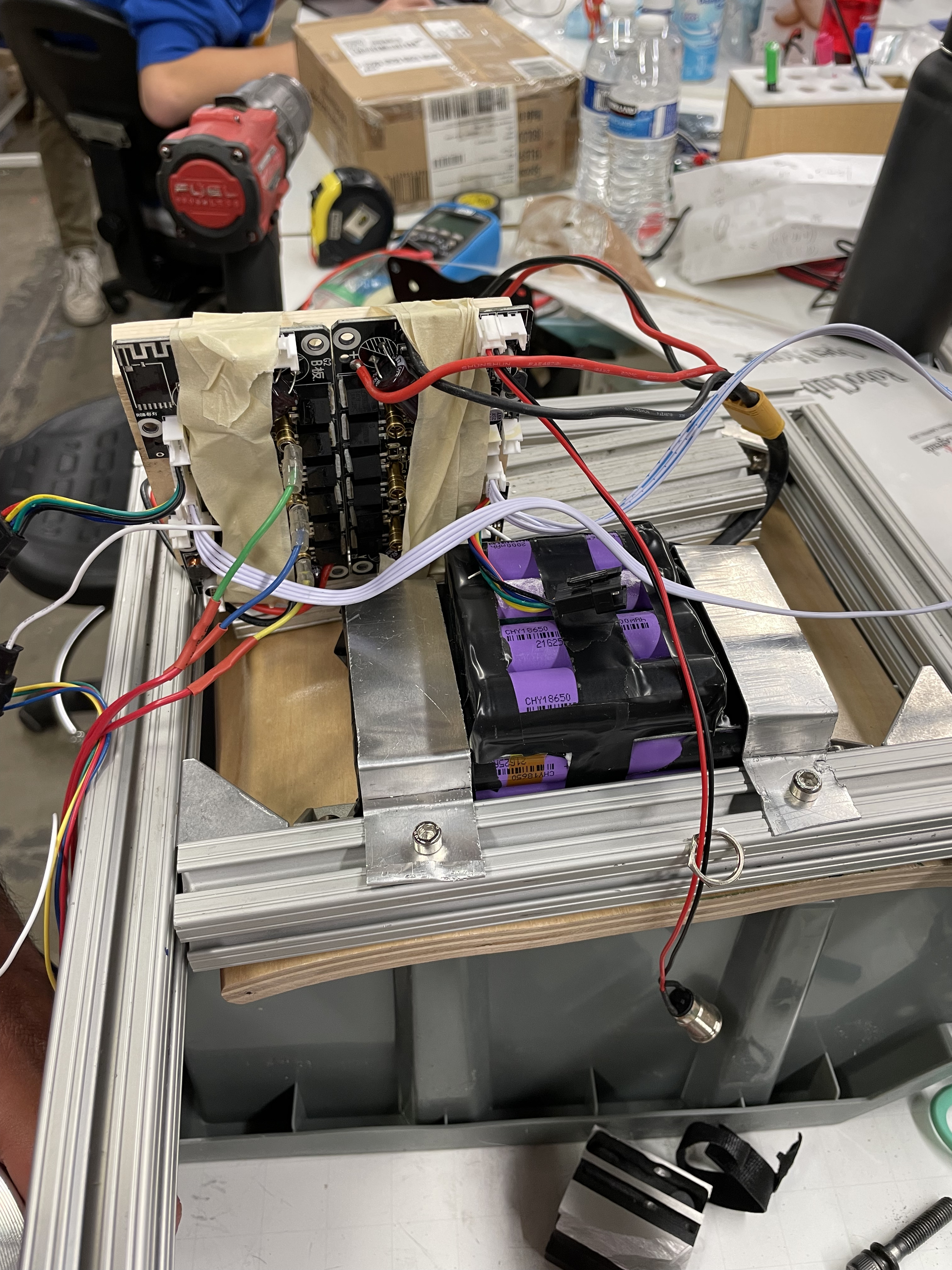

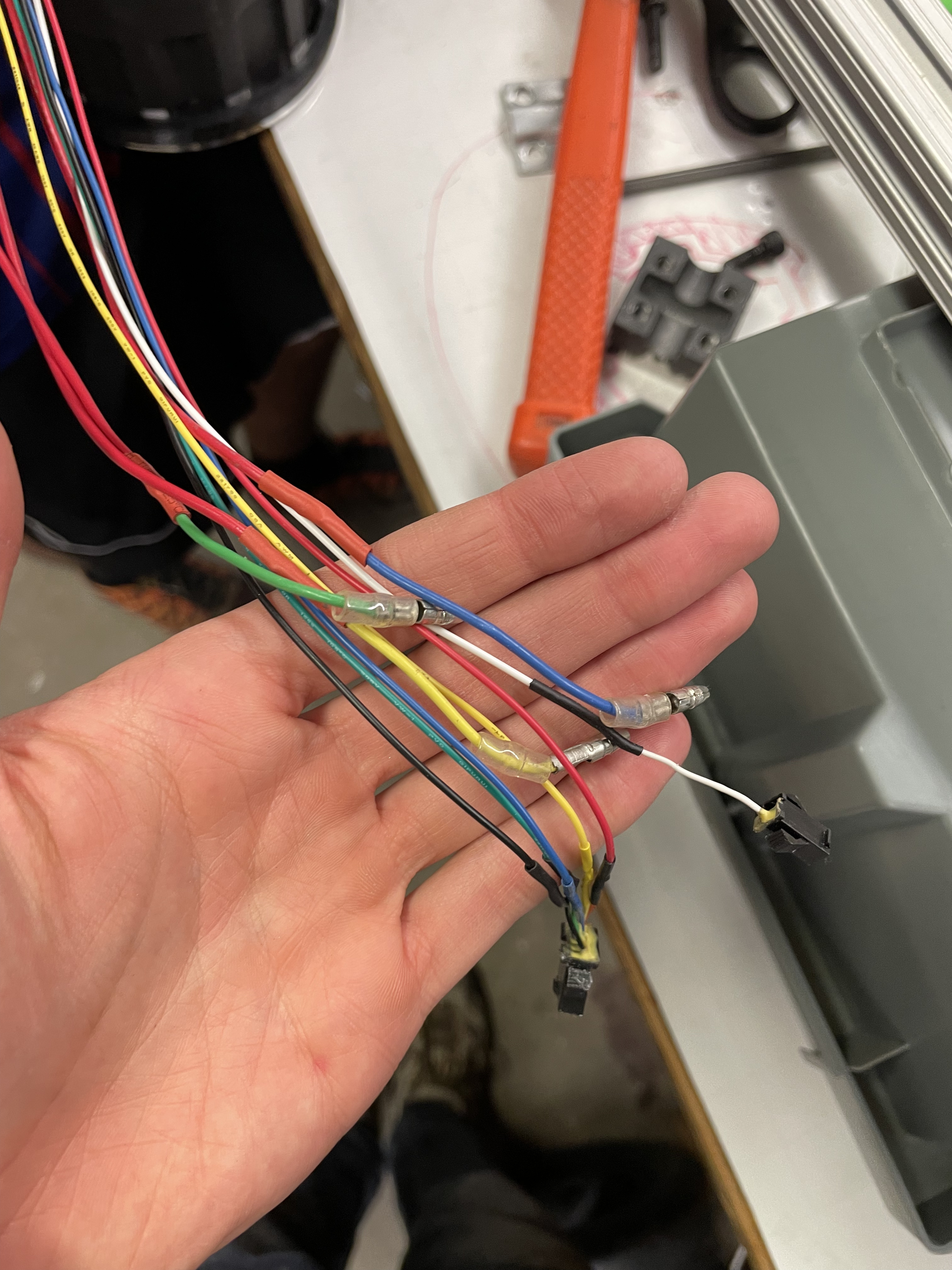

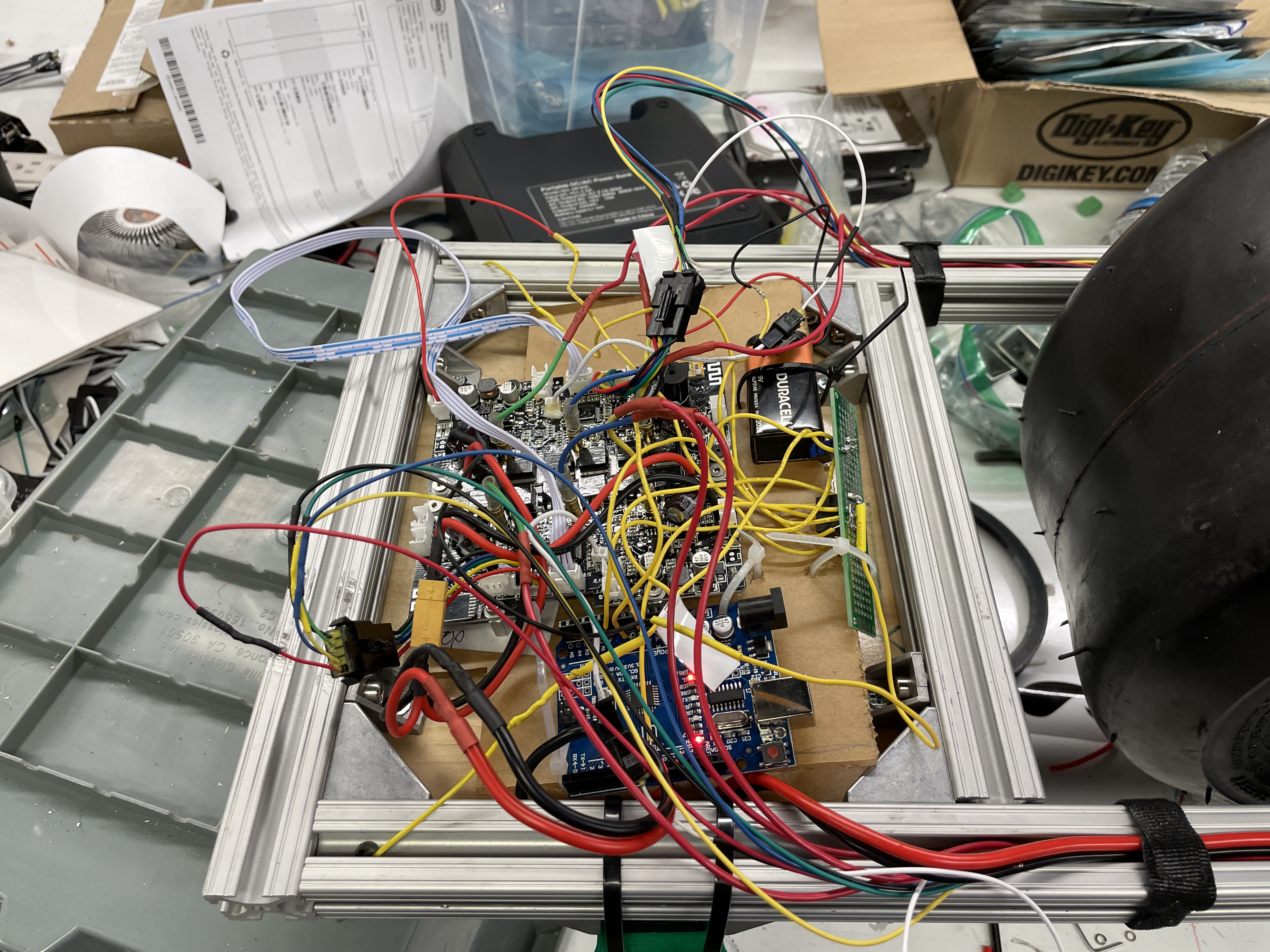

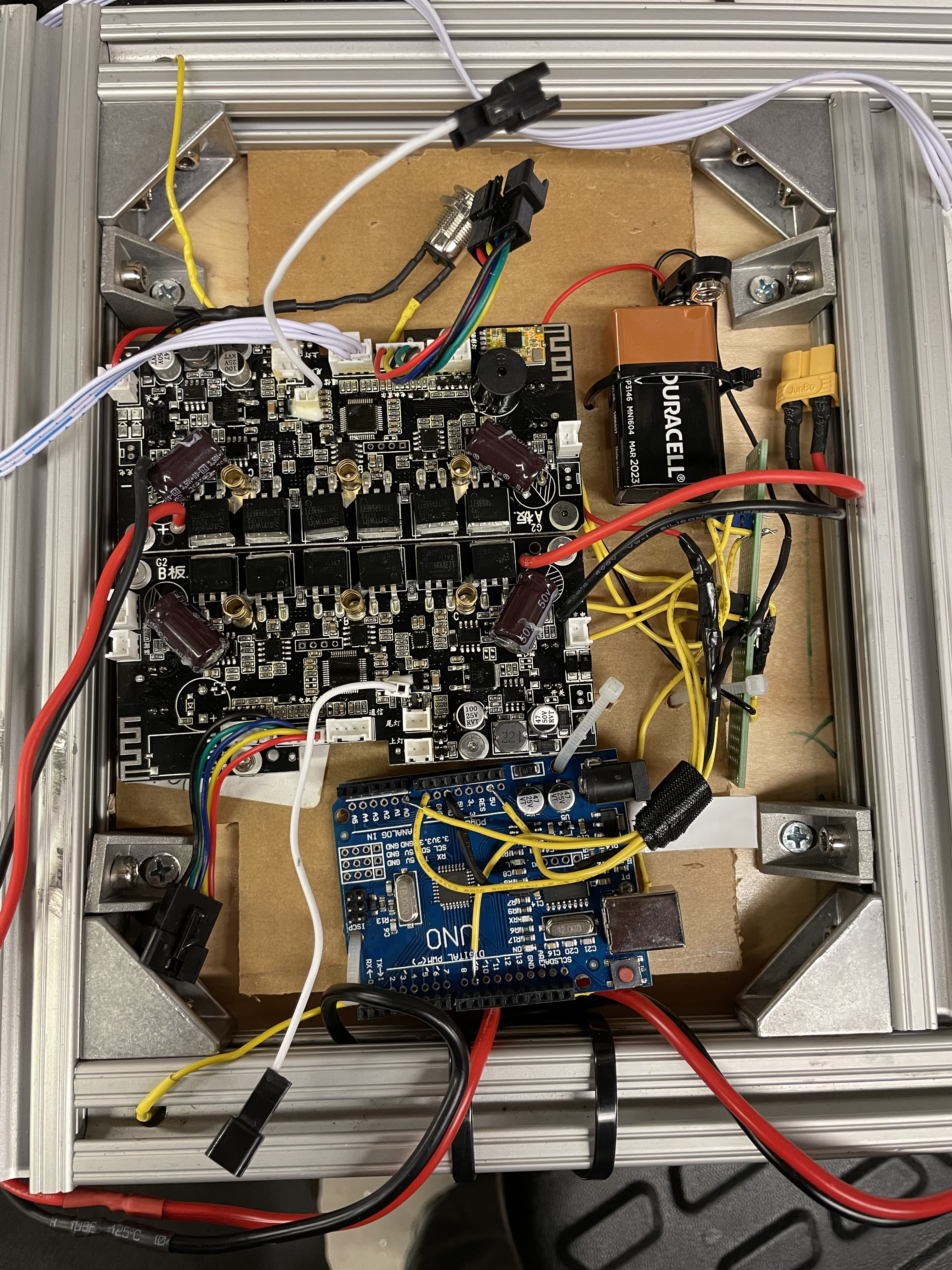

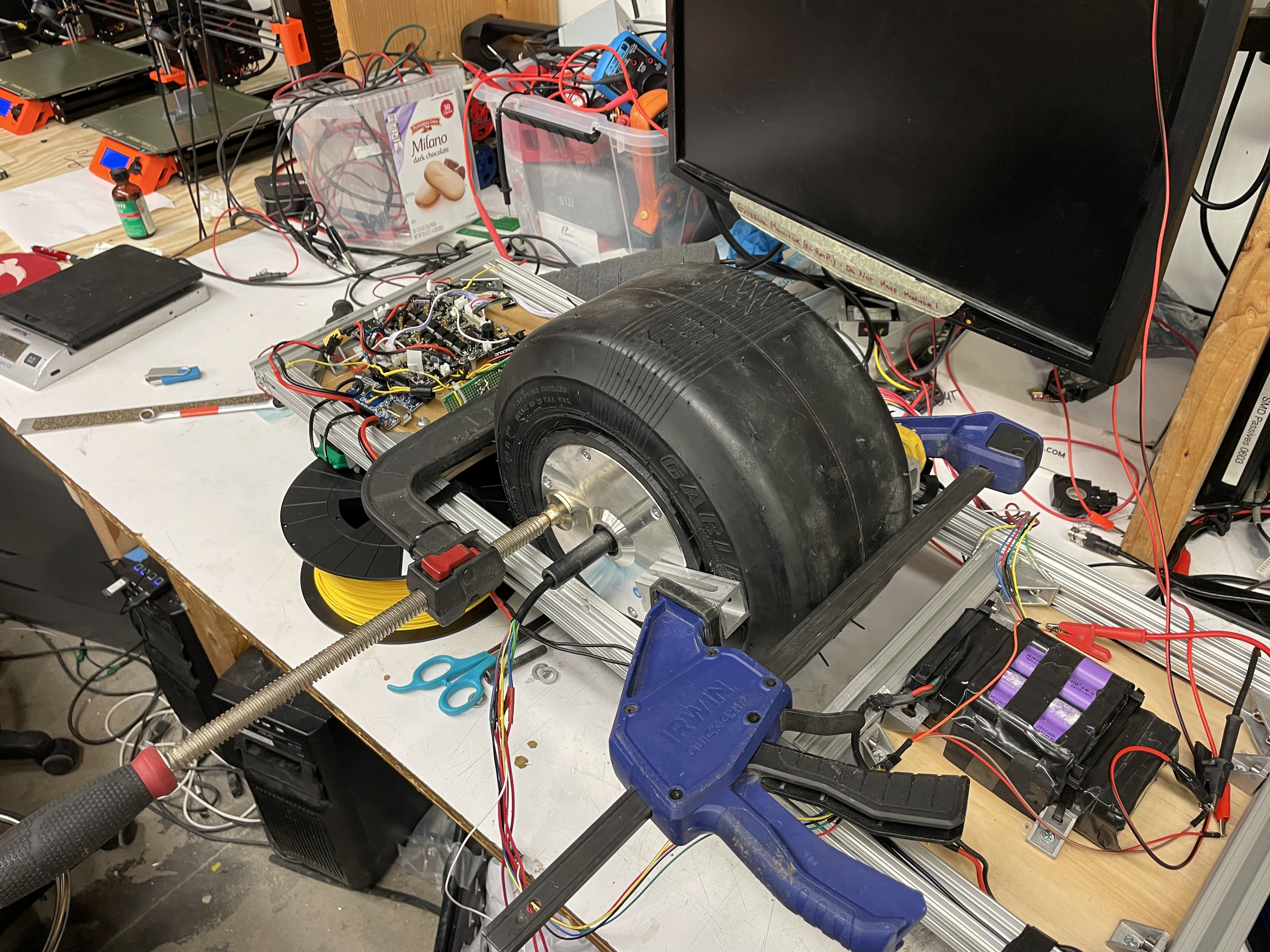

Day 5: Created motor and battery wire harnesses, improved axle mounts and ran first big test which just made a lot of scary noises. (turns out BOTH bearings are necessary).

Alby Penney

22 Jan 2022, 10:41 p.m. EST

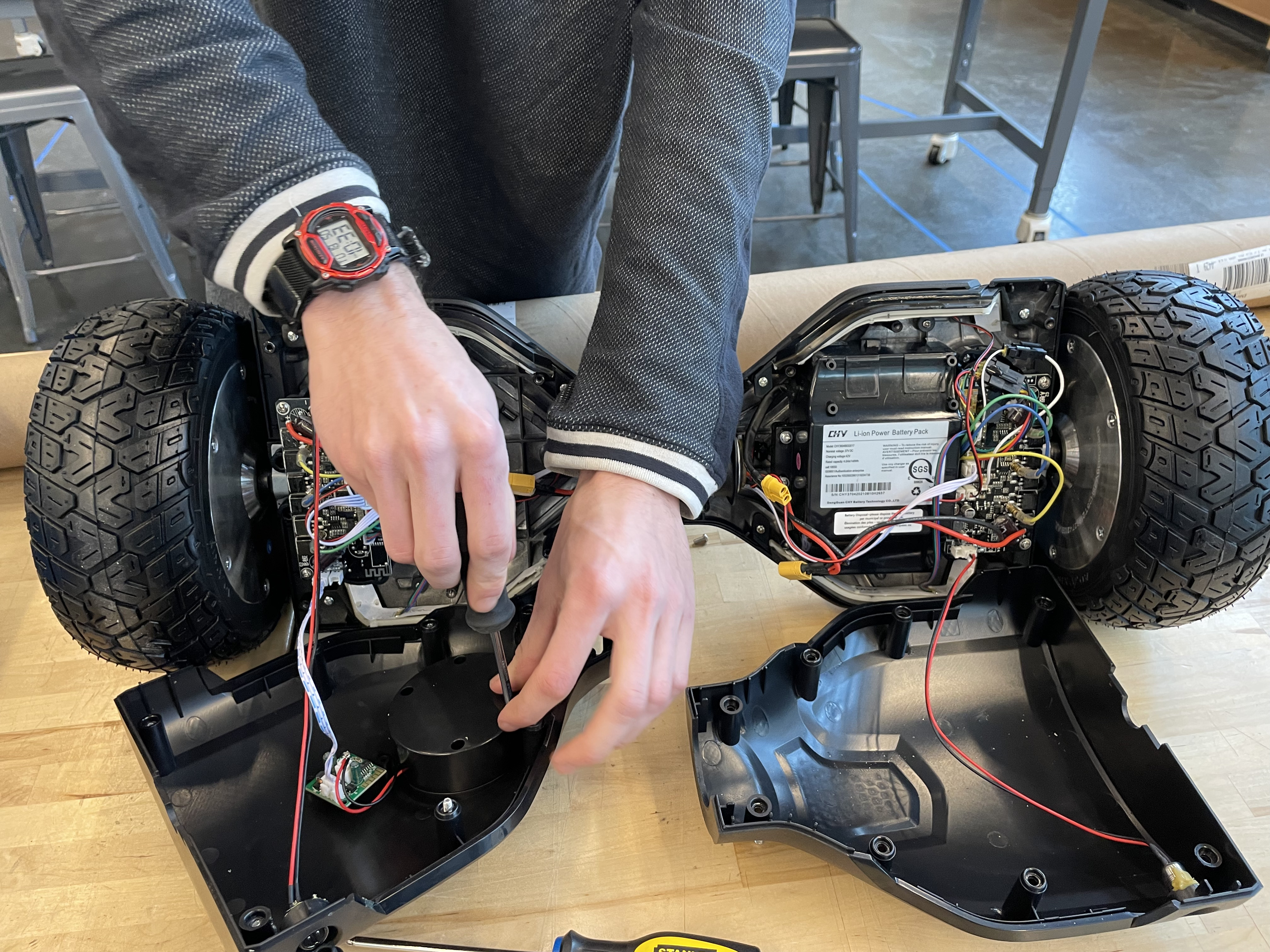

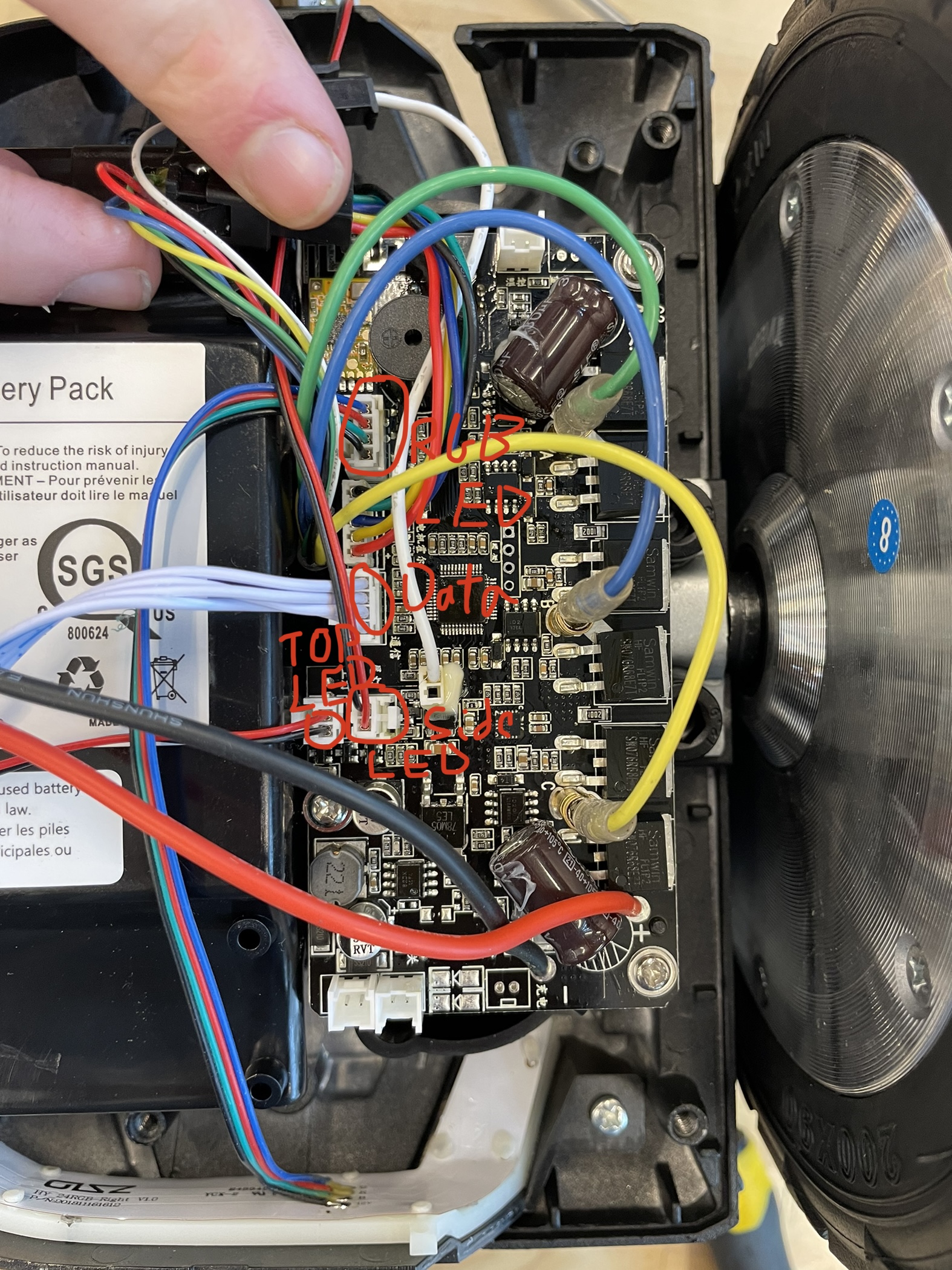

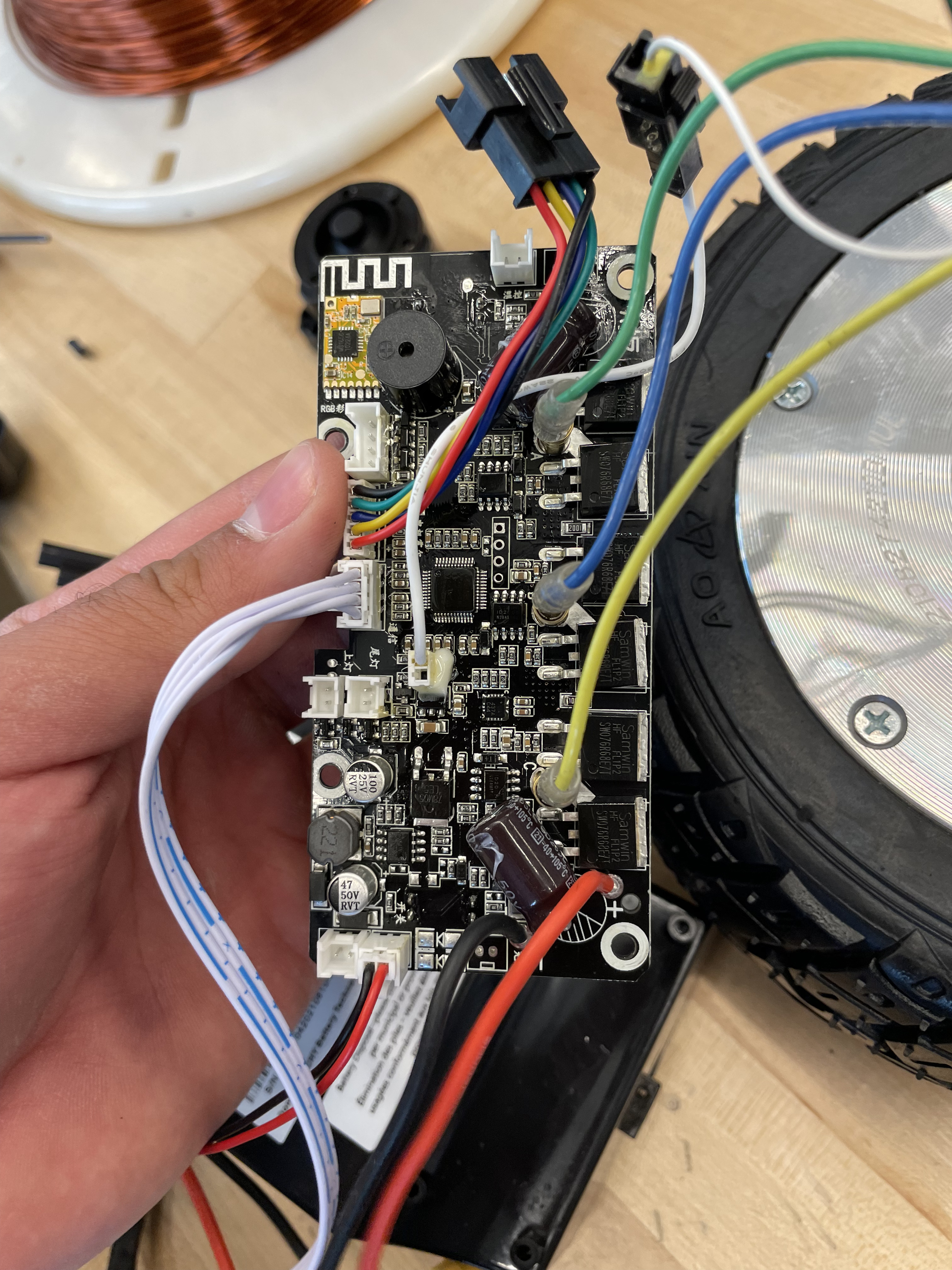

Day 1: Picked up parts and fully disassembled hoverboard (after some nerve-racking riding around techspark). We removed mounting brackets and attempted unsuccessfully to bolt together the two hubs.

Alby Penney

13 Feb 2022, 2:06 p.m. EST

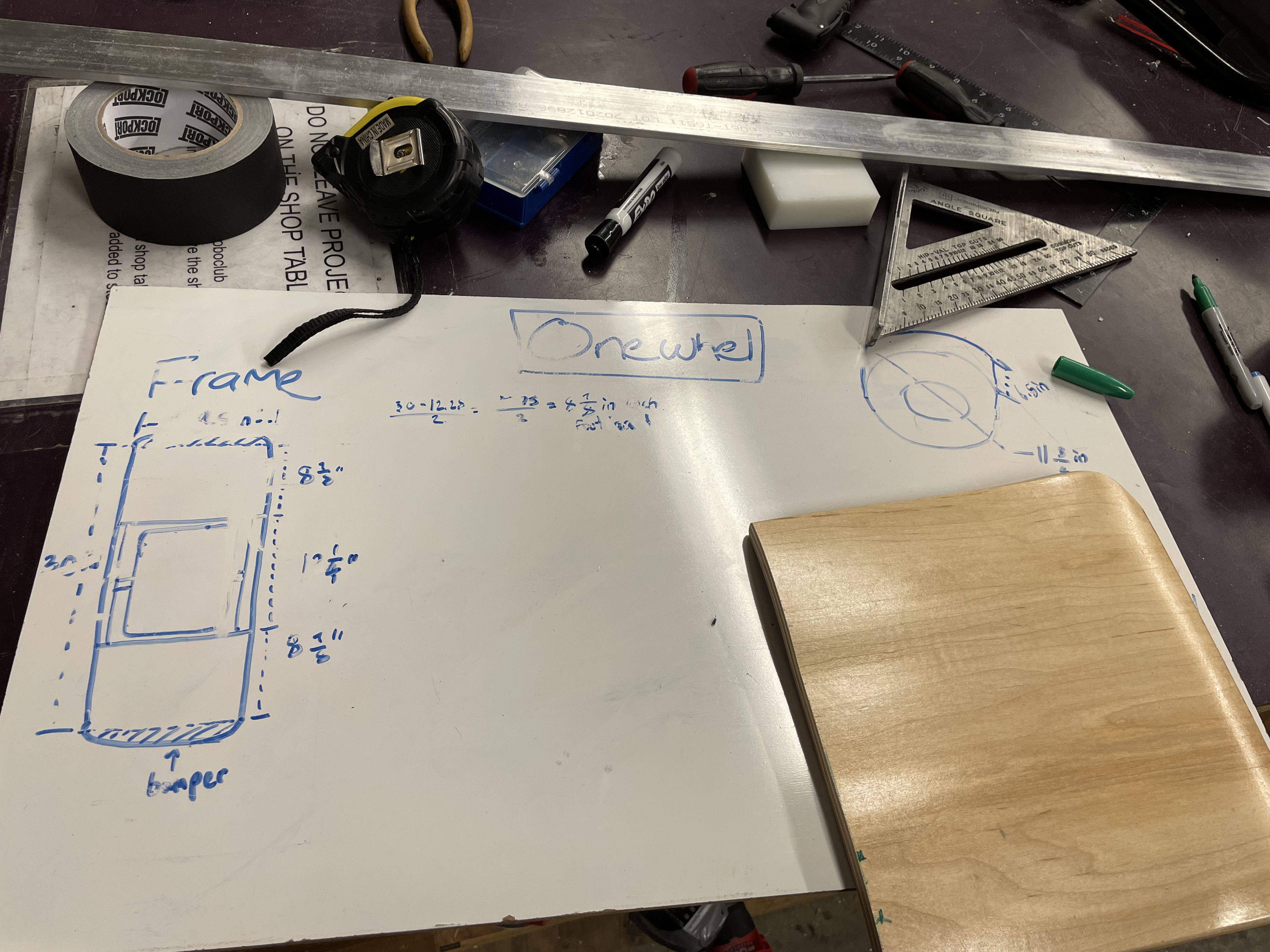

Day 2.5: Completed full tire assembly and developed frame design sketches based on collected measurements from tire assembly.

Alby Penney

13 Feb 2022, 2:05 p.m. EST

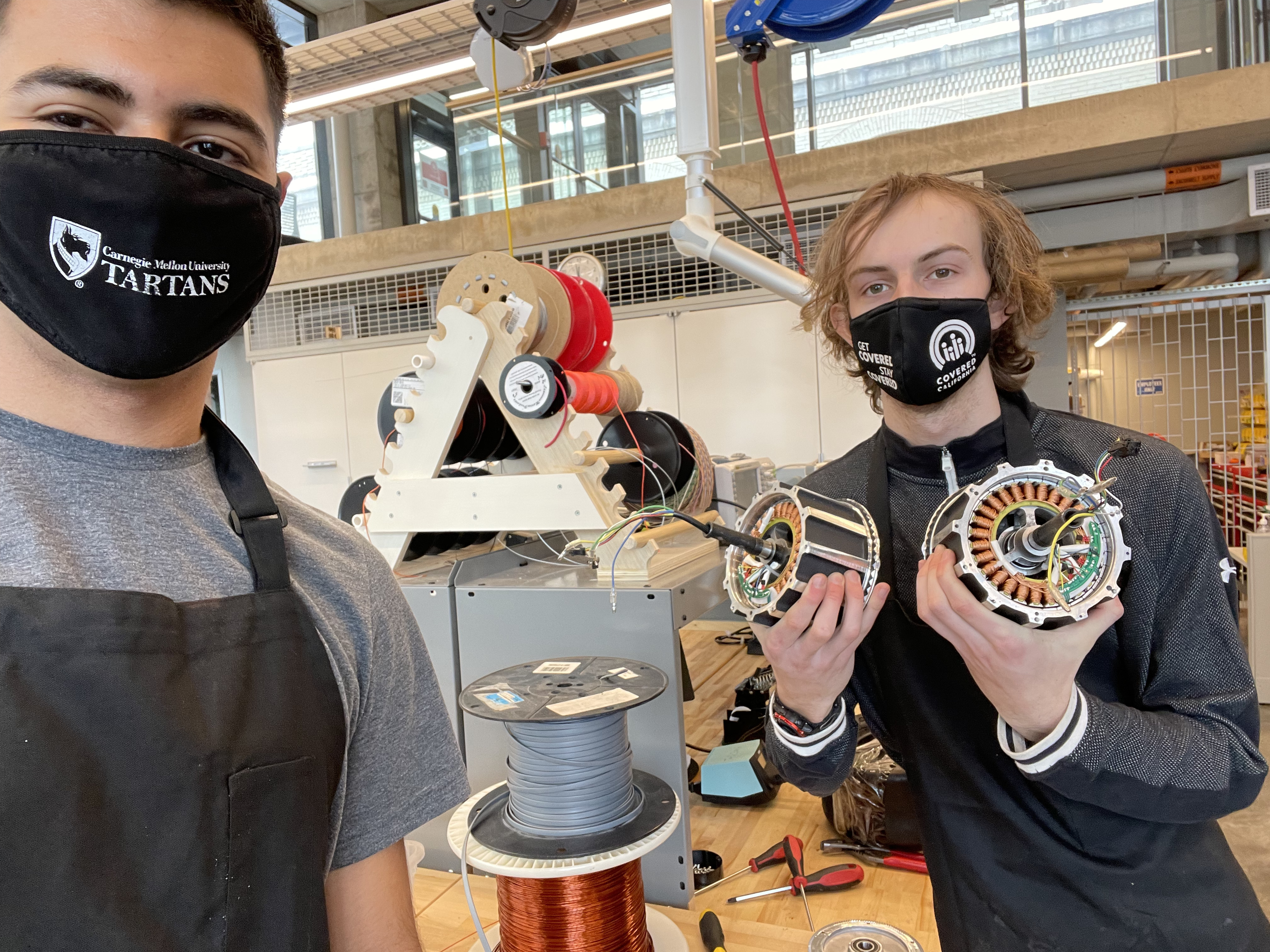

Day 3: Short day, Continued frame design, 3d printed non-fitting hub supports far too many times out of PLA until we discovered the magic of flexible TPU 95.

Alby Penney

13 Feb 2022, 2:06 p.m. EST

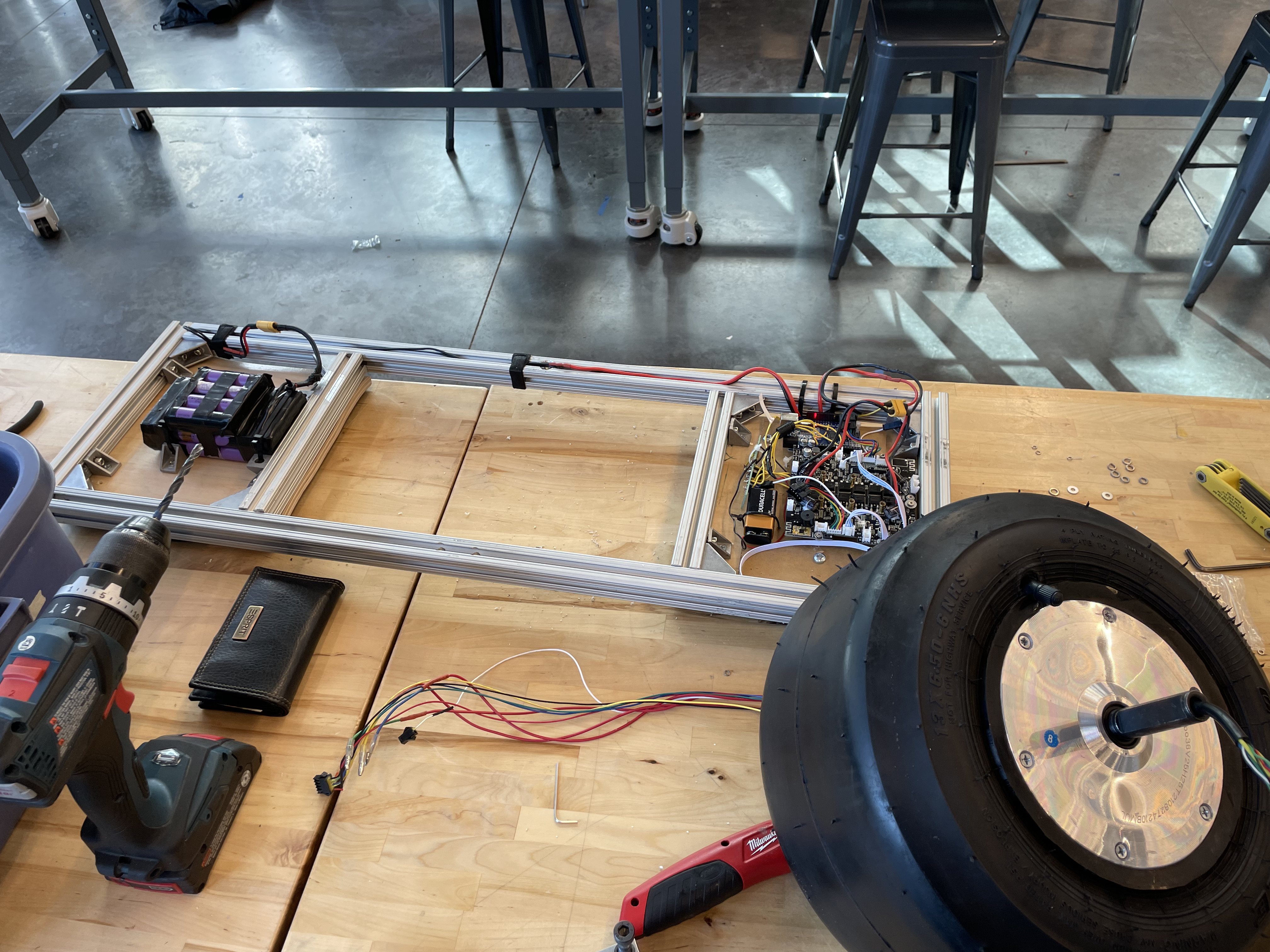

Day 4: Frame day, ditched C-channel and used 80/20 aluminum extrusion instead to build first prototype frame with footboards.

Alby Penney

13 Feb 2022, 2:07 p.m. EST

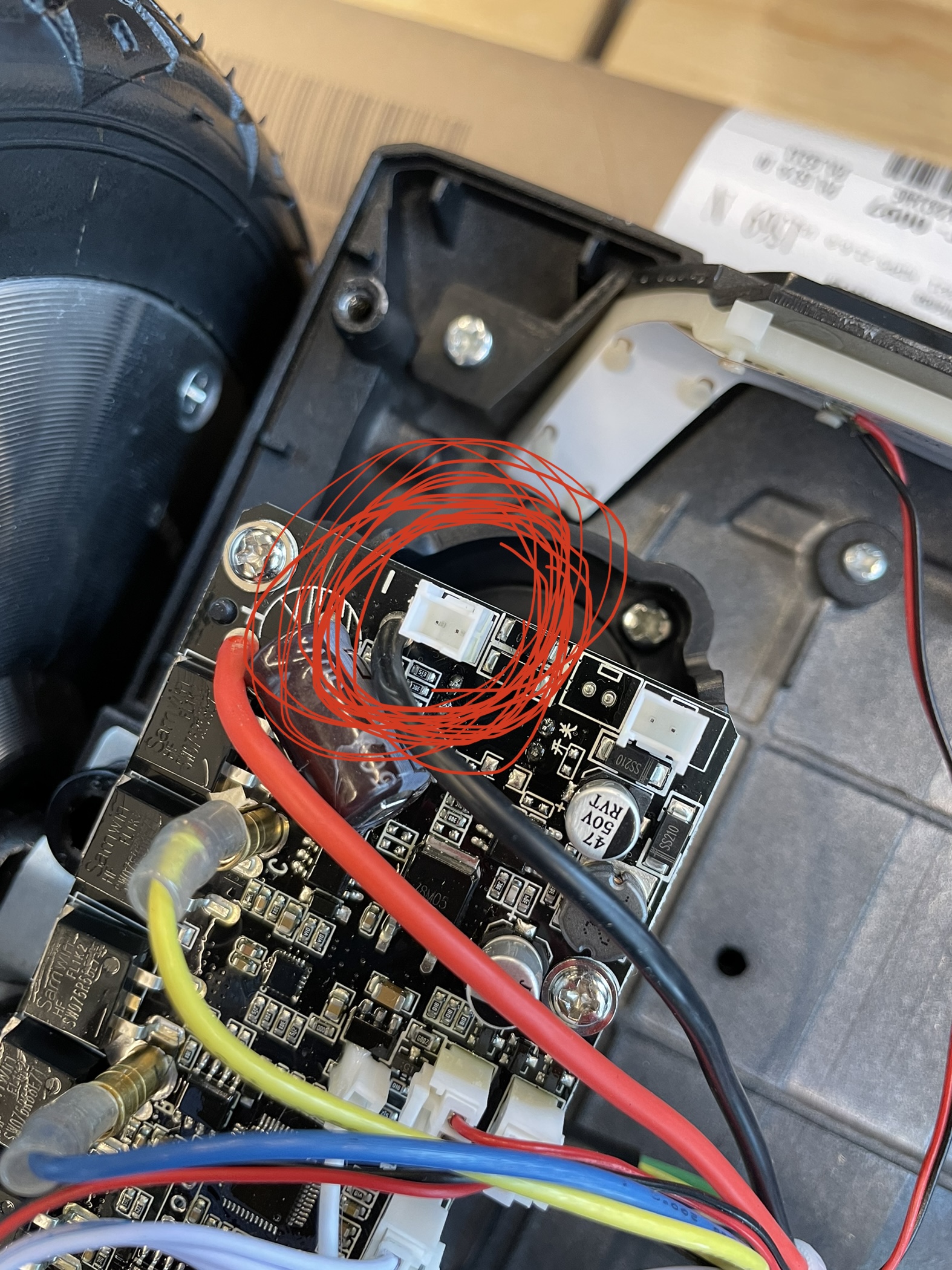

Day 6: Discovered a unique challenge to combining 2 wheels into 1: aligning the BLDC motor magnets. Initially the magnets were misaligned by 4 degrees, which is exactly half the width of a magnet, resulting in out-of-phase signals to the motors from each controller that prevented the motors from turning synchronously! After realigning both the magnets and hall-effect sensors, we noticed a much smoother operation.

Alby Penney

13 Feb 2022, 2:07 p.m. EST

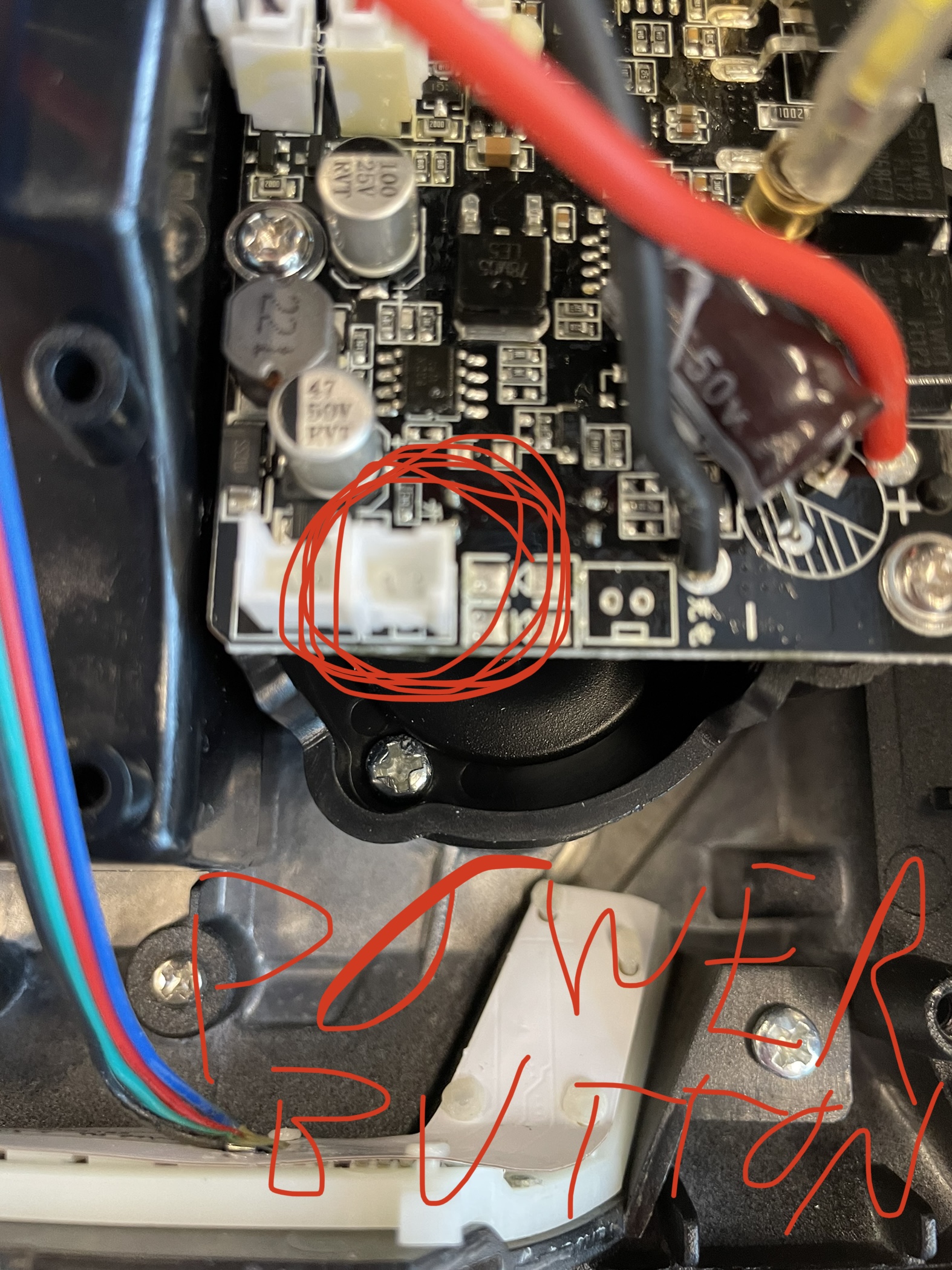

Day 7: A great tragedy struck, we tested replacement board, which was broken from the start ;( and also fried the 2 sideboards from the initial parts list. ESD safety should not be taken lightly!

Alby Penney

13 Feb 2022, 12:39 p.m. EST

Day 2: Discovered that the stator is removable, so we achieved the priority milestone of making one wheel from two and its only downhill from this point on.

David Barajas

13 Feb 2022, 2:22 p.m. EST

Day 7.5: Links for all the videos:

https://drive.google.com/file/d/18CNbLsKYzM0Zr4...

https://drive.google.com/file/d/1GYVL5bNBWkYE5b...

https://drive.google.com/file/d/1P3ZWB3ZmIIBpyo...

https://drive.google.com/file/d/1rheEpzJBMai6vQ...

https://drive.google.com/file/d/1rheEpzJBMai6vQ...

https://drive.google.com/file/d/1O22ASHA39mWKBi...

https://drive.google.com/file/d/1O22ASHA39mWKBi...

https://drive.google.com/file/d/1JeE5y-YoK3_Mzx...

https://drive.google.com/file/d/13pxZTJDN3B-Uap...

https://drive.google.com/file/d/1b7cdK5oJ0ybBbV...

https://drive.google.com/file/d/1GOPUOuCJxvqbVp...

https://drive.google.com/file/d/1Lo6XbKV5j_tmNM...